HEAT SHIELD INSULATION

HEAT SHIELD INSULATION FEATURES & BENEFITS

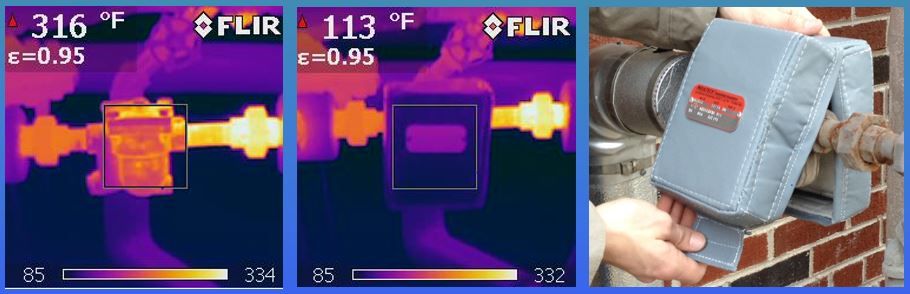

Shannon Heat Shield Insulation is a low-cost insulation solution for steam components that facility managers typically ignore. Shannon Heat Shields deliver safety and energy efficiency for steam traps and boiler doors. Create a safer work environment by lowering surface temperatures on critical applications and enhance your V.P.P. (Volunteer Protection Program ) with our simple solution. By delivering a high-quality, proven design, Shannon can improve steam quality and condensate return temperature, which equates to improved production efficiencies and reduced wear and tear on critical assets on the steam system such as steam traps and boilers. Heat Shield designs are application specific; no guessing on what specification works or the quality of fit and finish. Shannon Heat Shields are expected to last 15 years or more. Heat Shields can be removed and re-installed within minutes; it’s easy on easy off giving immediate access for service, inspection or repair.

Shannon Heat Shield Insulation is compliant to OSHA standards for exposed heated surfaces wherever there is a potential for injury. OSHA standards include; 1910.261(k)(11), 1910.262(c)(9), 1910.23(c)(3), 1910.147 & 1910.132(a), Section 5(a)(1) of the OSHA act.

Proven Design & Design Construction

Shannon Heat Shield engineered systems are CAD/CNC produced. We create exact fit and finish, making installation, removal and re-installation, simple and easy. With a design library approaching 7 million CAD files, our proven library of designs assure success.

Learn more about our thermal blanket insulation solutions.

LIFETIME SAVINGS: $ 743.18/15 YEARS

Refinery – Armstrong®

Steam Trap / Trap Valve Station

Design: LT500HS-AG – 3/32” Thickness

Fastener: Velcro Flaps

Purpose: Energy Savings & Personnel Protection

SAMPLE OF SAVINGS

1 EACH STEAM TRAP

Gestra® MK45 Steam Trap

Surface Temperature: 274 F

Ambient Temp: 80 F

Steam Cost: $10.00 / mm BTU

Design: LT500HS-AG – 3/32” Thickness

Fastener: Velcro® Flaps

Purpose: Energy Savings & Personnel Protection

Operating Cost Bare: $65.80/Year

Cost of Heat Shield: $65.00

Install Cost: $13.00

Annual Savings: $49.55/Year

Payback Period: 17.2 Months

LIFETIME SAVINGS: $ 743.18/15 YEARS

FEATURES: Double sewn construction, U.S. quality fabrics, ID tagging, grommet for ultra sound access.

HEAT SHIELD INSULATION HIGHLIGHTS

- Self-contained insulation system

- Double sewn construction

- Easy on & easy off

- Ideal for outdoor use

- ASTM/UL/ISO tested

- CAD/CNC/ERP QA/QC approach

- Non-porous outer jacketing

- Standardized designs for all models & makes

- Compelling energy savings

- Ideal for personnel protection

FIELD SERVICE & SALES SUPPORT

Shannon engineered systems are represented and supported by technical sales representatives that embrace the sale and support of the sale with expert steam system knowledge. We take pride in offering comprehensive Energy Survey Services following the steam trap survey or further energy survey work, tracking a steam system, identifying new radiant heat loss opportunities on steam systems beyond the steam trap. Shannon’s proven energy savings are fully endorsed by utility rebate programs in the U.S. and Canada.