ACOUSTIC BLANKETS

ADDRESSING RADIANT NOISE ON FAN & BLOWER HOUSINGS

Shannon GES has developed noise reduction solutions to address radiant sound energy on fan and blower housings. Design considerations for temperature and environmental conditions, as well as noise reduction targets (4-15 Dba). Shannon GES Acoustic Blankets Solutions are ASTM tested, field validated and OEM endorsed. A self-contained insulation system, designed to fit complex surface geometry, integral fasteners make installation quick and easy.

Application: Industrial Fan Housing

Design: LT450A-TT – 2” Thickness

2.9lb/SF – Surface Mass

Reduction: 8-10Dba

DESIGN FEATURES

- PTFE Fiberglass Jacketing

- Double Sewn / Tri-Fold Binding Edges

- Stainless Steel Integral Fasteners

- Velcro / Vinyl Acoustic Flaps

- Stainless Steel Embossed / ID Tags

- CAD/CNC/ERP Approach for Quality Fit / Finish

- Testing: ASTM: E1222 & ISO 15665 (Insertion Loss Test)

- 4 Dba to 15 Dba Reduction

Application: Rooftop Axial Fan Housing

Design: LT450A-TT – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 6 Dba

HVAC LIQUID CHILLER

COMPRESSOR, COMPRESSOR INLET, MOTOR HOUSING

Design: LT250A-VP

Performance: 4.0-5.0 dBA Reduction

24” PROCESS PIPING

Design: LT450A-TT

Performance: 10-12 dBA Reduction

Application: Single Stage Compressor Housing

Design: LT450A-TT – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 6 Dba

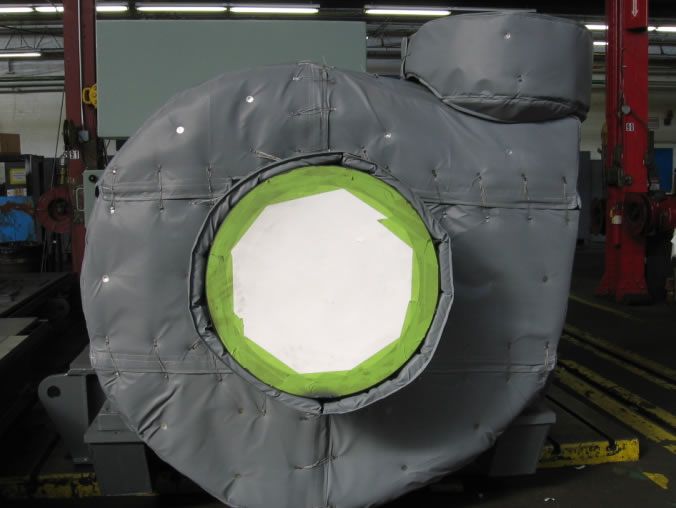

Application: Single Stage Blower Housing

Design: LT450A-TT – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 8 Dba

Application: Single Stage Centrifugal Compressor Housing

Design: LT450A-TT – 2” Thickness

2.8lb/SF – Surface Mass

Reduction: 8-10 Dba

Application: Inline Axial Fan Housing

Design: LT450A-TT – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 6 Dba

Application: Single Stage Compressor Housing

Design: LT450A-TT – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 6 Dba

Application: Fan Housing

Design: LT250A-VP – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 6 Dba

Application: Forced Draft Fan Housing

Design: LT450A-TT – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 6 Dba

RELATED ARTICLES

CO2 Emissions: Carbon Capture vs. Carbon Reduction

Carbon capture vs. carbon reduction – What roles do they play? What roles do carbon capture and carbon reduction with insulation play in combating CO2 emissions and climate change. They serve different purposes. Let’s compare them: 1. Carbon Capture &...

Steam Cost Calculator – 5 Reasons Why You Need To Know Your Steam Costs

Why You Should Know Your Steam Energy Costs Steam energy is a critical component of many industrial processes. From manufacturing to power generation, steam plays a vital role in keeping our industries running smoothly. However, understanding the cost of steam...

Plexiglass Safety Shield? Compare to Shannon Heat Shield for Steam Trap Burn Safety

Plexiglass safety shield? Mitigate burn risk and save energy at the same time, by treating the problem not the symptom. Specify Shannon Easy on/Easy Off reusable Heat Shields applied to your steam traps directly. Look at this example: Application The below...