THERMAL BLANKETS

THERMAL BLANKET INSULATION FOR THE PROCESS INDUSTRY

The solution to problem insulation for the process industry on all types of steam process equipment. The removable, reusable features of Shannon Thermal Blankets products drastically lower operation costs, shorten down-time, save valuable energy, improve the work environment and reduce labor costs associated with installation, removal and reinstallation.

Custom designed and self-contained. This means quality construction for specific applications, quality designs retrofitted to field conditions and design features that make Shannon friendly for the field mechanic.

CAD technology for maximum design accuracy. Through years of information gathering, Shannon can produce standard and customized designs for equipment including condensate pumps, all types of valves, slip and bellows expansion joints, ball joints, strainers and steam traps. Shannon can engineer blankets for even the most difficult geometric surfaces (e.g., steam turbines).

Self-contained insulation system, constructed of a high density insulation filler with a fully encapsulated outer jacketing. The outer jacketing is double sewn and bound at the closing seams. The jacketing and sewn construction ensure long lasting protection to the insulation filler.

Learn more about our Thermal Blanket Insulation Solutions.

BIO-CHEMICAL PLANT

Main Steam Supply Header – Post M&V Survey

Design: LT450TT – 1.5” thickness (Green PTFE Fabric)

3.5” x 1.5” identification tag for each blanket piece.

Each stainless steel or aluminum tag 1/8” embossed lettering for individual piece labeling is riveted directly or indirectly to the outer jacketing surface of our thermal blankets. The tag becomes an integral part for each of our thermal blankets. When the blanket is removed, the tag will identify its place at the time of installation.

Accommodates temperature extremes (Ambient to 1100ºF). With many design specifications established as industry standards, optimum service life can be expected with cost efficiency. Consult a factory representative for further information on thermal blankets.

Not just a product purchase. Our goal is problem solving. Shannon offers energy surveys for steam and process industry systems, sound surveys for noisy equipment or engineering services for packaged systems. Our knowledge of insulation is broad and our abilities as a full service blanket insulation manufacturer are unprecedented in the industry.

Energy Surveys – Shannon offers a calculated heat loss review of your steam system. With a number of survey formats to choose from, Blanket Insulation, for example, can be installed on flanged piping systems — which lack proper thermal performance — or any exposed areas (e.g., valves, flanges, fittings, PRVs strainers, etc.). Shannon can also calculate heat loss. From the heat loss calculations, operating costs and payback period can be determined. The energy survey becomes a personalized heat loss summary of your steam system, with detailed descriptions of specific locations and fittings. Typical energy surveys show payback periods between one and two years. When calculating the economic benefit of the initial investment, gains are as high as 15 times the initial investment. Not many capital projects match these economies. Engineering Services – Shannon is a market leader in design, product development and application. Product line catalogs are available for both thermal, acoustic and safety. We are a blanket manufacturer bridging the gap between theory and applications.

Support – Shannon supplies insulation systems to the domestic end user market and the O.E.M. and international markets through a global network of sales managers, manufacturer’s representatives and distributors.

PERFORMANCE HIGHLIGHTS

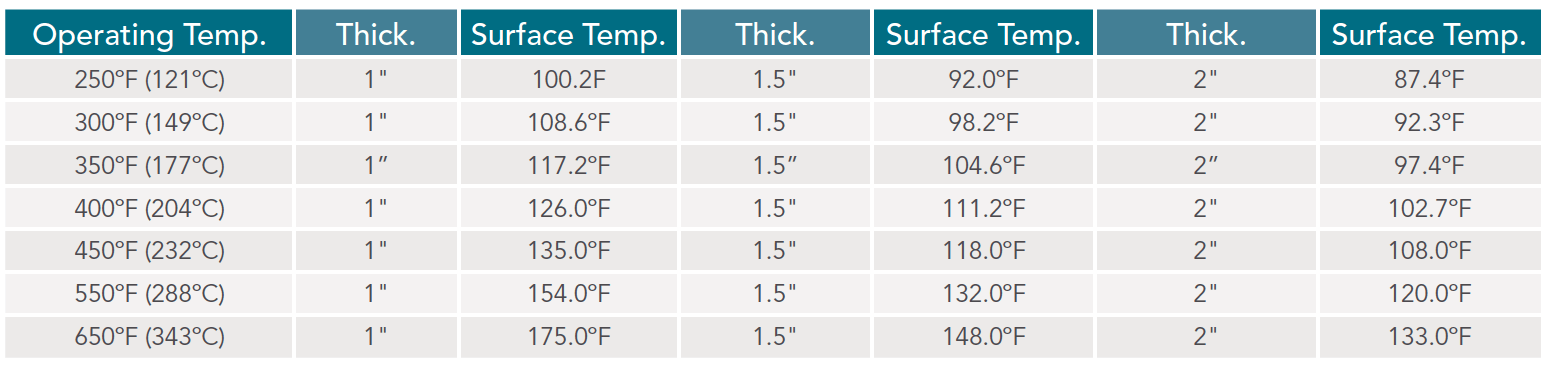

- This cold face surface temperatures reference should be used as guidelines for blanket thickness design.

- The cold face surface temperature of the blanket should approach ambient temperature conditions.

- The economic thickness of the blanket should consider blanket cost to thermal performance.

- Heat loss calculations are based on a 70ºF ambient using a flat surface condition.

DESIGN FEATURES

1. “D”ring strap fastener with Velcro® tab

2. Stainless steel wiretwist fastener

3. Side release buckle with nylon strap fastener

1. Stainless steel wiretwist fastener

2. Side release buckle with nylon strap fastener

3. “D”ring strap fastener with Velcro® tab

1. Wind flap with draw cord

2. Two-piece construction (separate body and bonnet)

3. Riveted and embossed ID tag

4. Double sewn lock stitch construction 5. Teflon® PTFE fiberglass cloth