ACOUSTIC BLANKET SOLUTIONS

ACOUSTIC SHIELDS & BLANKET INSULATION FOR SOUND ATTENUATION

Acoustic Blanket Solutions are pre-engineered thermal acoustical insulation systems designed to reduce harmful noise levels and improve the surrounding work environment.

Custom-fit, through CAD technology allowing versatility in equipment coverage. Virtually any irregular surface can be insulated and multipiece designs are typical for most equipment applications.

Top quality design construction. The recommended design LT450A-TT features an inner and outer chemical resistant Teflon® fiberglass cloth, with high density fiberglass mat and barium sulfate loaded vinyl.

Removable and reusable. Removable acoustic insulation blanket pieces can be installed with minimal effort and fastened with a stainless steel wiretwist, metal spring tensioner, or metal D-ring strap with Velcro® tab. Installation requires no tools or materials.

Acoustic Blanket Systems Reduce Harmful Noise At The Source

Learn more about our Acoustic Blanket Insulation solutions.

16”x18” CENTRIFUGAL PUMP

Design: LT450A-TT – 1.5” thick

6.0 dBA Reduction

DESIGN FEATURES

- Double Sewn and Binded Seams

- Durable PTFE Teflon® Impregnated Fiberglass Clot

- Aluminum Nameplate Embossed Lettering With Tag Description

- Stainless Steel Lacing Hardware With Featured Wiretwist Fastener

- Extended Velcro® Flap on Closing Seams

- High Density Mass Loaded Vinyl (Reflection)

- High Density Needled Fiberglass Mat Filler (Absorption)

ADVANTAGES

- Installed with plant personnel

- Removable and reusable numerous times

- A closed insulation system

- Custom-fit to existing conditions

- An ideal replacement for Asbestos

- Vibration resistant

APPLICATIONS

- Ejectors

- Gear Box Casings

- Steam and Gas

- Turbine Casings

- Compressor Housings

- Exhaust Ducting

- Pressure Reducing Valves

- Custom Sound Curtains

- Liquid Chillers

ACOUSTIC SHIELD SCROLL COMPRESSOR

Design: LT250AS

6.0 dBA Reduction

HVAC LIQUID CHILLER

COMPRESSOR, COMPRESSOR INLET, MOTOR HOUSING

Design: LT250A-VP

Performance: 4.0-5.0 dBA Reduction

24” PROCESS PIPING

Design: LT450A-TT

Performance: 10-12 dBA Reduction

CENTRIFUGAL LIQUID CHILLER

Design: LT250A-VP 1.5” thick

Wiretwist / Velcro® Flap Fasteners

Performance: 7 dBA Reduction

AXIAL FAN HOUSING

Design: LT450A-TT – 1.5” thick

Wiretwist / Velcro® Flap Fasteners

Performance: 6 dBA Reduction

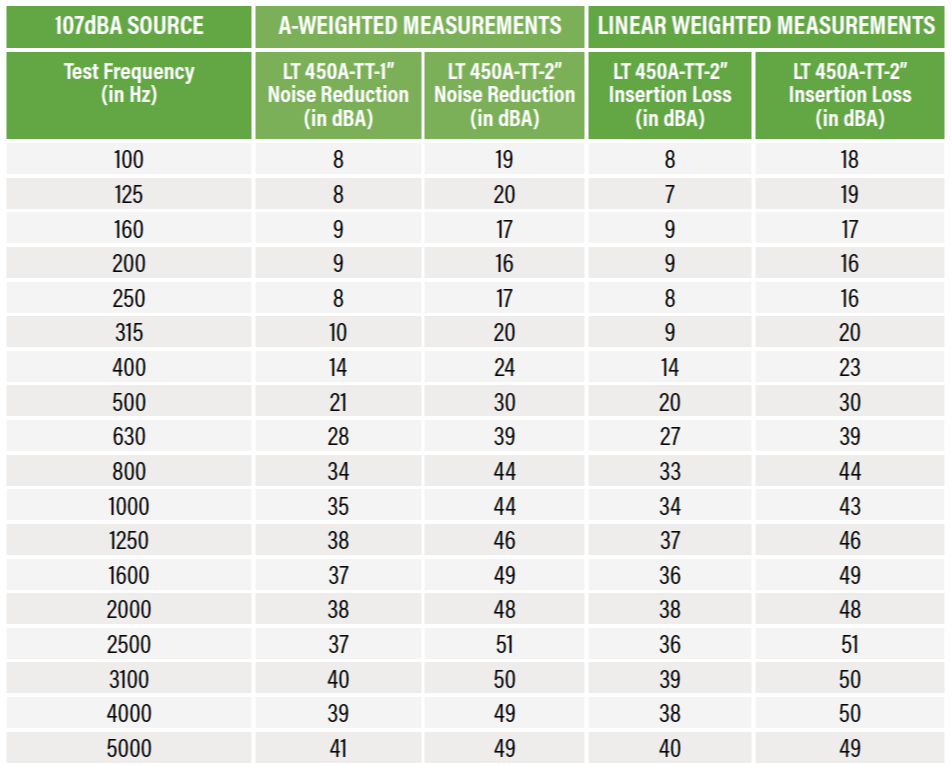

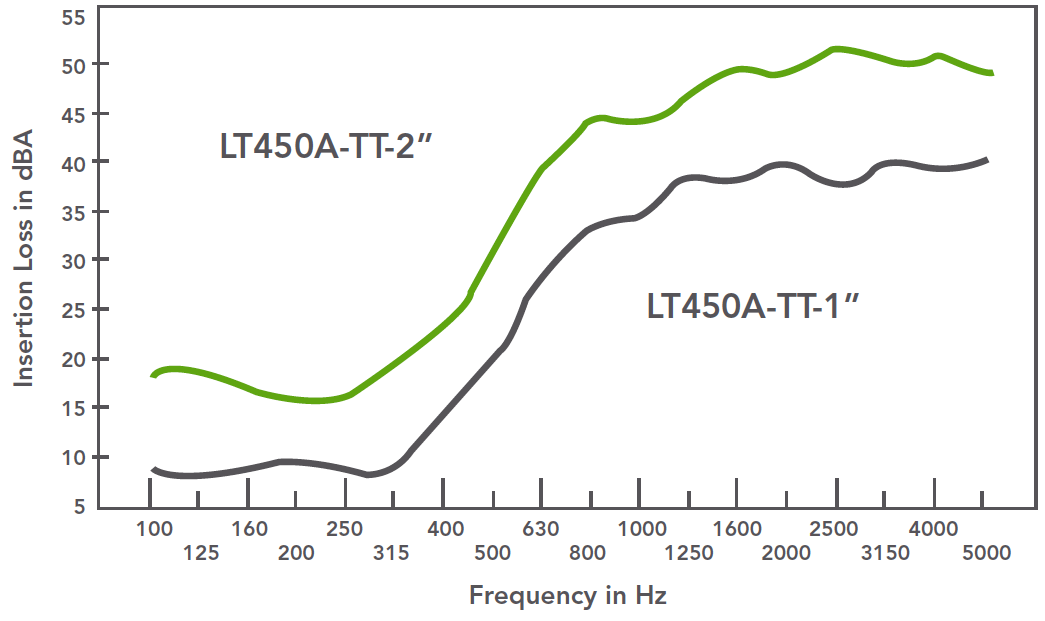

TEST RESULTS FOR ACOUSTIC BLANKETS

With the following measured in the A-Weighting, the total noise reduction from the 107 dBA loudspeaker level over a 100-5000 Hz frequency band would be: 20.8 dBA for design LT450A-TT-1″ Thickness and 29.5 dBA for design LT450ATT- 2″ Thickness.

This data represent (ASTM) Test Procedure E-1222-87 for the laboratory measurement of the insertion loss of pipe lagging systems. Shannon will not be warranted for performance results of Blanket Insulation expressed or implied.

UL1709 TEST METHOD

INSERTION LOSS PERFORMANCE COMPARISONS

RELATED ARTICLES

CO2 Emissions: Carbon Capture vs. Carbon Reduction

Carbon capture vs. carbon reduction – What roles do they play? What roles do carbon capture and carbon reduction with insulation play in combating CO2 emissions and climate change. They serve different purposes. Let’s compare them: 1. Carbon Capture &...

Steam Cost Calculator – 5 Reasons Why You Need To Know Your Steam Costs

Why You Should Know Your Steam Energy Costs Steam energy is a critical component of many industrial processes. From manufacturing to power generation, steam plays a vital role in keeping our industries running smoothly. However, understanding the cost of steam...

Plexiglass Safety Shield? Compare to Shannon Heat Shield for Steam Trap Burn Safety

Plexiglass safety shield? Mitigate burn risk and save energy at the same time, by treating the problem not the symptom. Specify Shannon Easy on/Easy Off reusable Heat Shields applied to your steam traps directly. Look at this example: Application The below...