ENERGY EFFICIENCY FOR BREAKFAST CEREAL PRODUCTION

We won’t sugar coat it. According to Energystar.gov, the U.S. breakfast cereal industry spends over $130 Million on purchased fuels and electricity annually. The Energy Star Energy Guide (link below) elaborates on the variety of opportunities available at individual plants to reduce energy consumption in a a cost effective manner. The guide includes estimates of expected savings in energy and energy related costs, based on case study data from breakfast cereal processing facilities and related industries.

All the details in EnergyStar.gov Energy Guide:

Energy Efficiency Improvement and Cost Saving Opportunities for Breakfast Cereal Production 2018

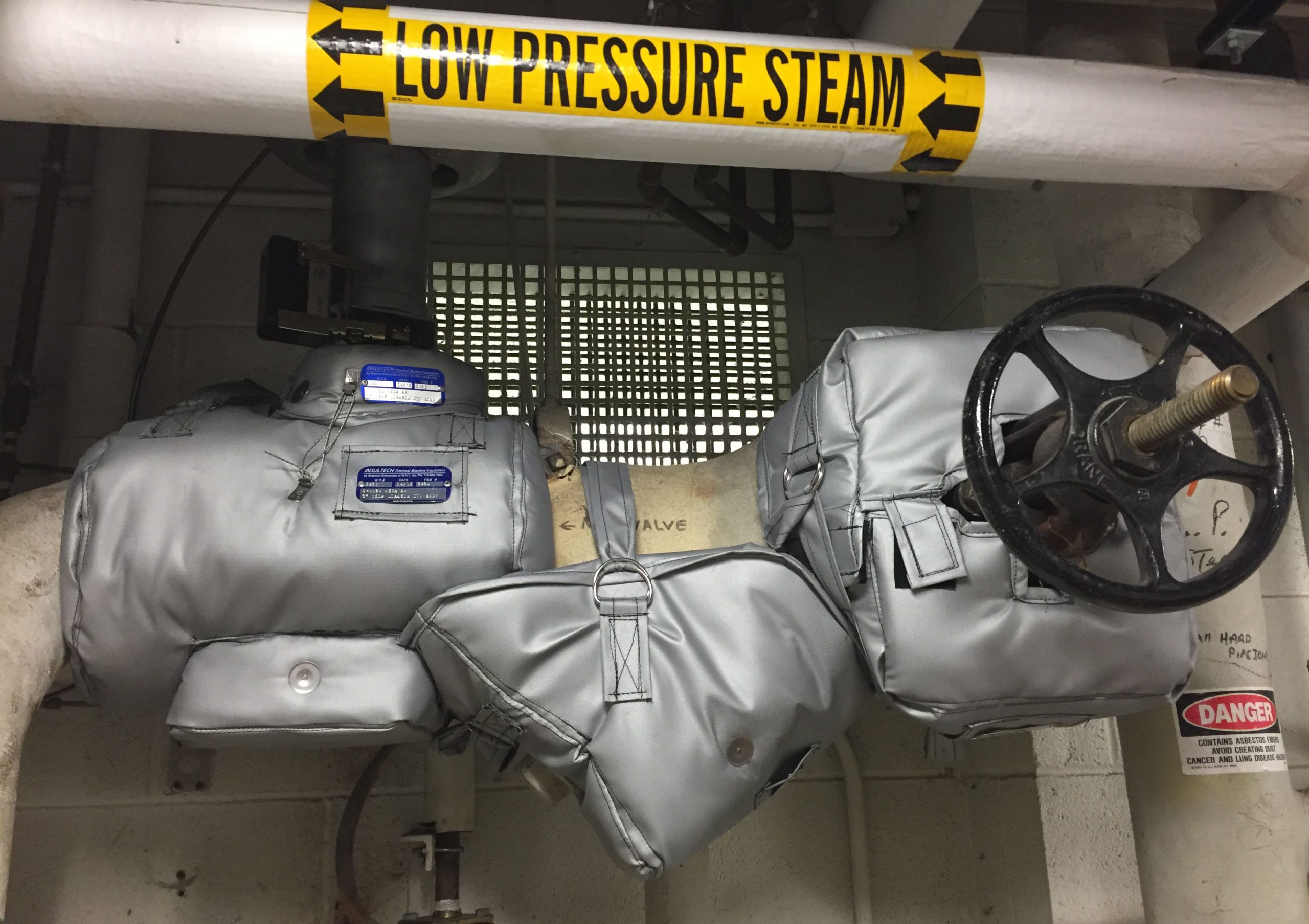

Condensate Receiver in Cereal Processing plant. The removable, reusable Thermal Insulation Blanket accommodates Steam connections and Sight Glass connections.

Insulation For Energy Efficiency

The Energy Guide lists the measure “Insulation” as a suggested energy saving opportunity in many areas.

These include Steam Distribution, the Cooking Process, the Drying and Toasting Process and the Forming Process.

Whatever your favorite cereal variety might be, you can guess our favorite variety of energy efficiency is removable, reusable insulation.

Contact us for more information on free thermal energy surveys, Shannon GES engineered reusable mechanical Insulation blankets and pay back periods.