NORTH TONAWANDA, N.Y. – December 16, 2020 – Shannon Global Energy Solutions, a provider, designer and maker of reusable thermal and acoustic insulation, has developed the Shannon Steam Heat Kits to prevent freezing and/or maintain fluid viscosity for refineries, chemical plants, shipping, food and beverage and many other industrial applications. The kits, which act as a source of heat, consist of steam-carrying, stainless steel tubing and wrap around components such as gate valves, Coriolis meters and pump housings.

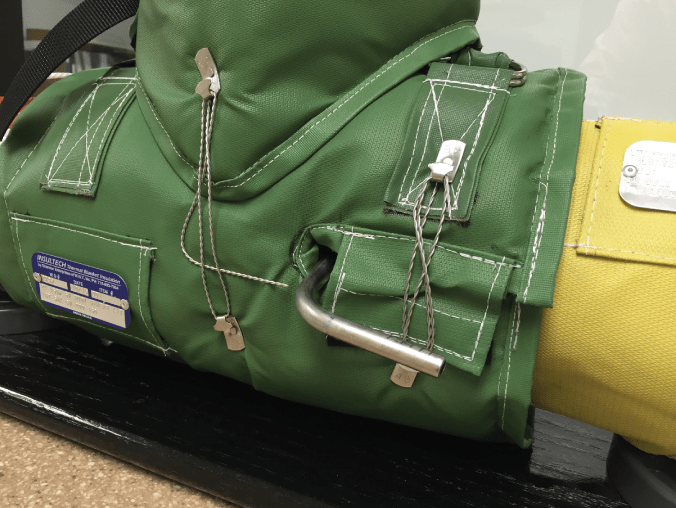

Shannon also sells its Steam Heat Trace Kits with custom-designed reusable thermal blanket insulation, which a mechanic can use to cover the kits and further reduce heat loss.

“Electrical heat tracing isn’t always an option, especially in hazardous environments, so our Steam Hit Kits are another choice,” said Joe Lauria, director of Sales & Marketing for Shannon. “Facility managers can achieve optimal performance, safety and efficiency with our kits by mitigating the effect of temperature swings on the flow of liquids.”

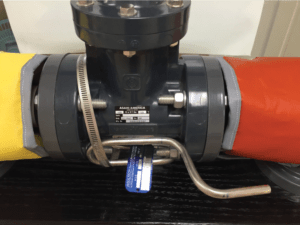

Shannon creates each Steam Heat Kit, or steam coil assembly, with a CAD system to maximize the surface area being traced with tubing and minimize installation time by mirroring the geometry of the component or heavy equipment being wrapped. Shannon makes its Steam Heat Kits from either 304 or 316 stainless steel seamless tubing to withstand harsh weather.

The inlet and outlet connections for the Steam Heat Kits are placed at the mating flange center point, allowing a mechanic to install the kit with minimal effort. Since Shannon configures every kit for the component it’s meant to protect, mechanics can slip the kit into place without damaging either kit or component. Delivering a custom-designed kit to workers means they no longer have to fashion a heat trace kit from scratch with tools on the job site, which wastes time bending tubes, making errors or using extra material. For commonly sold steam components like gate and control valves, Shannon has standard off-the-shelf kits ready to deliver. Customers can buy any kit with or without a custom Shannon INSULTECH® thermal insulation blanket.

“Our flareless fittings create a visible, heavy bite allowing easy inspection and a rear compression grip firmly holding the nut and tubing,” adds Frank Kovacs, CEO of Shannon. “We also offer stainless steel ANSI Class 300 flange adapters. Either connection offers easy-on, easy-off performance.”

About Shannon Global Energy Solutions

Since 1988, Shannon has engineered and manufactured insulation solutions for energy conservation, thermal efficiency, noise reduction and safety. With its CAD-CNC-ERP approach to design and manufacturing, Shannon is the world leader for reusable and removable insulation.