Reusable Insulation for Gate valves provides major energy savings, safety and maintenance advantages

Gate valves are one of the most common industrial valve types. It’s important to learn about the best insulation for gate valves. Here’s a clear, practical overview:

What is a Gate Valve

A gate valve is a linear-motion valve used to start or stop the flow of a fluid- liquid or gaseous.

It works by raising or lowering a flat or wedge-shaped “gate” inside the flow path.

Key features

- Full flow when open – minimal pressure drop

- Good for on/off service – not ideal for throttling

- Common in steam, hot water, oil, gas, and chemical systems

- Often paired with high-temperature or high-pressure insulation systems

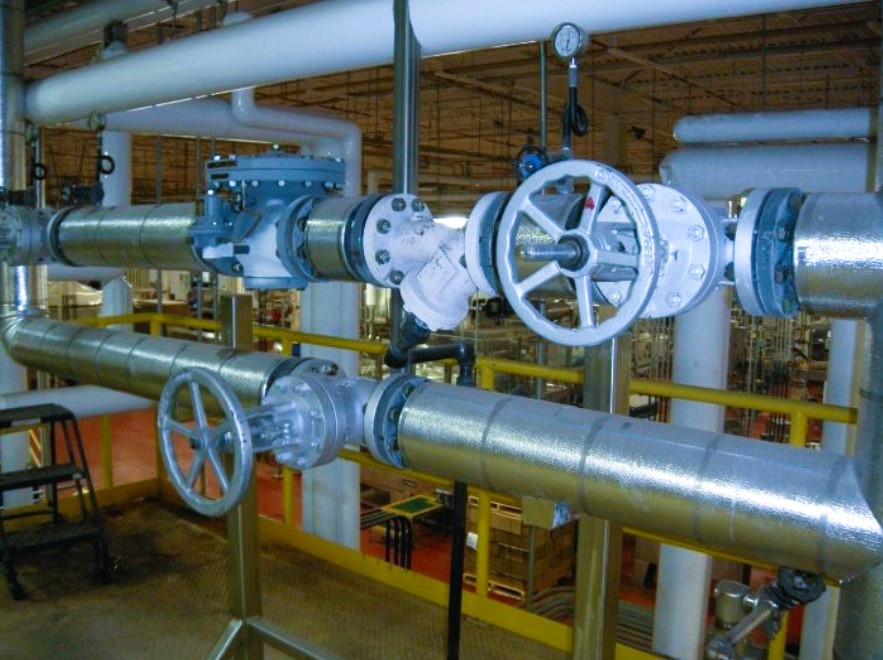

Gate valves have complex geometry and large surface area

The bare surface area of a single 6-inch 150# Gate Valve is equal to the surface area of 4 feet of 6-inch Pipe.

| Gate Valve Size 6″ 150# | Surface area in Sq Feet | Linear Feet of 6″ Pipe | |

| 1 | 7.3 SF | equal to | 4.2 LF |

| 8 | 58.4 SF | equal to | 33.67 LF |

As shown in the table above, You wouldn’t leave 4 feet of pipe uninsulated, let alone, over 33 feet of pipe uninsulated!

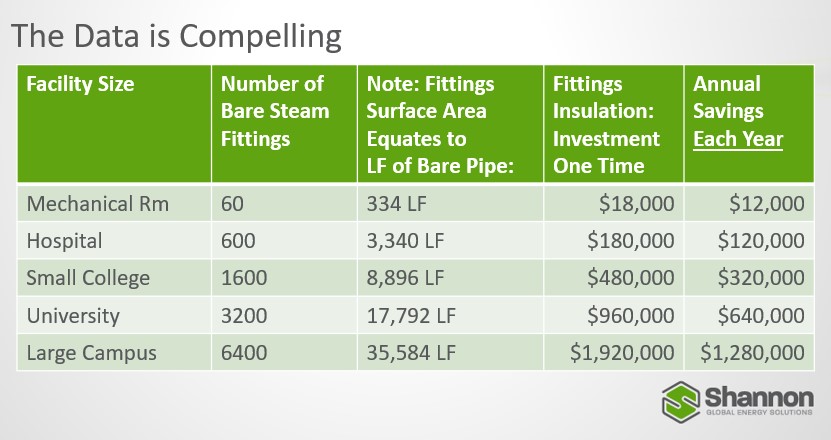

Compare the Surface area of BARE Gate valves and other steam fittings to Linear feet of BARE pipe. What sizes are in your facility and how many? Every day that you delay insulating your complex geometry valves, strainers, flanges and other fittings is money wasted.

Why Insulate Gate Valves?

Significant energy loss

Uninsulated valves leak heat far faster than insulated pipe runs.

Each valve becomes a “hot spot” that wastes fuel and increases operating costs.

Safety Risks

Surface temperatures on steam or hot fluid systems can exceed 400°F (204°C), even higher in process industries. These temperatures pose burn hazards for personnel working nearby. And increase ambient temperature of mechanical rooms.

System Efficiency

Heat Loss reduces Steam Quality, Process Temperature Stability and System Performance.

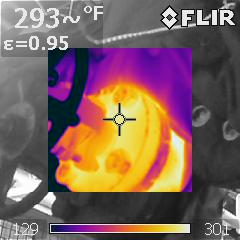

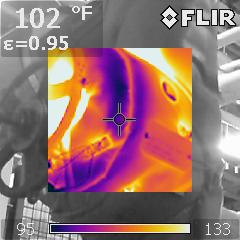

Measurement and Verification

Shannon can provide an M & V report to show that expected results were obtained.

Shown are the Thermographic images of a Gate Valve Before (bare) 293F and After with a Shannon Thermal Insulation Blanket, 102F:

Why Use Shannon Reusable Insulation for Gate Valves?

Perfect Fit for Irregular Shapes

Gate valves vary widely in:

- Size

- Bonnet shape

- Actuator configuration

Shannon Reusable Insulation blankets are made to fit each component, including the bonnet as a separate blanket. eliminating hot spots.

Easy Removal for Maintenance

Traditional hard insulation must be cut off and discarded during inspection and maintenance.

Flexible, Shannon gate valve blankets are removable and reusable for long term performance – expect a 15 year service life. Removed and re-installed in minutes by maintenance staff with integral fasteners.

Huge energy savings

Insulating Gate Valves can save hundreds to thousands of dollars per year ( depending on temperature, size and quantity)

Long-Term Durability

Engineered and manufactured to exacting standards, they withstand harsh environments and repeated removal and reuse.

Consider this:

Gate Valves are often part of a complex system of fittings

Shannon Insulation Blankets are custom made to fit the valves and fittings that are part of your system. Experience and high-level knowledge of engineering insulation blankets for effective performance for a variety of configurations is key to optimizing energy efficiency. Here are some examples:

Summary

Gate valves are essential flow-control components but are major sources of heat loss when uninsulated,

Because they have a large surface area in their irregular shaped geometry. Since Gate Valves need to be easily accessible for inspection, maintenance and repair, Hard Conventional insulation is a Mistake.

Why Specifying Shannon Insultech® Blanket Insulation systems is The BEST mechanical Insulation Solution for Gate Valves to improve energy efficiency:

CAD Designed for exact fit & finish

CNC Produced for Accuracy and High Quality

Comprehensive Specifications to accommodate temperature and field condition

Each Gate Valve Blanket includes a Metal embossed ID plate with a QC code for identification

Integral fasteners for easy off- easy on

Design standards tested to ASTM, UL and ISO

In summary, insulating facility steam system components with high quality removeable, reusable insulation blankets, with custom fit and integral fasteners not only improves energy efficiency but also enhances safety and prolongs the gate valve’s lifespan. Consider it a cost-effective asset for better performance and reduced operational expenses.