Personnel Protection Guard For Steam Traps Introduction

Employee burns are costly to the employer and most importantly, to the employee. Personnel Protection guards and shields have been used as a safety measure and choosing the best method requires knowing the facts. For the Employer, a single recordable burn injury is estimated to be $47,192.00, according to the Occupational Safety & Health Administration Company Profitability Work Sheet

To recover from this cost, business performance must overcome these unnecessary costs by driving added profitability. For the employee, in addition to pain & suffering, the employee is saddled with unnecessary medical expenses and lost workdays. These costs do not reflect potential litigation and potential settlement costs derived from litigation.

Old Style Burn prevention safety practices

Typical Practices, for managing hot surfaces on steam traps, may include the assembly of a metal safety cage or personnel protection guard. This wraps around the steam trap and aims to prevent direct contact to the hot surface by an operator. The alternative are removeable reusable insulation heat shields.

Issues with the metal Personnel Protection Guard

Open Surface Condition

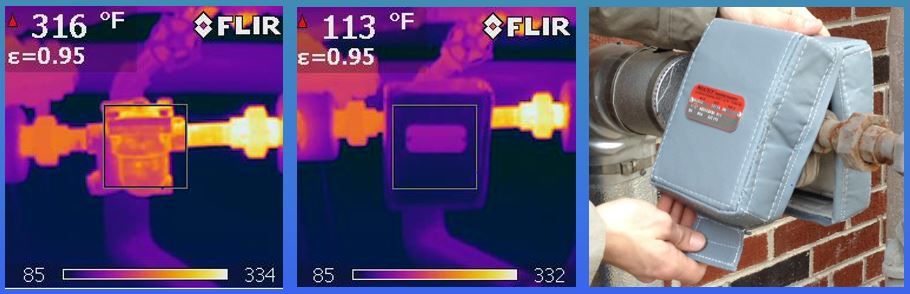

The metal guard is an expanded mesh or perforated metal enclosure. It is an open surface condition radiating heat. This open surface condition is susceptible to outdoor weather, rain, snow and wind which adds to the dissipation of heat or heat loss.

LIMITED ACCESS

The safety cage protects the employee but only has limited access for service inspection and repair. In some cases, the metal guard is locked with a pad lock to prevent access. This limits the operator, who no longer has the benefit of easy access.

What does the U.S. Department of energy suggest

“Effectively insulate inverted bucket traps with removable and reusable insulation. Thermostatic traps and disk traps should be insulated according to manufacturers’ specifications to ensure proper operation.”

The Case for Shannon removable reusable Insulation Shields

1. Burn Prevention

Mitigate risk factors of employee burns, lost workdays, and recordable incidents.

2. OSHA Compliance

Addresses OSHA 1910.261 (k) (11), 1910.262(9), 1910.23(3) for hot surfaces

3. Energy Efficiency

Heat Shield will capture 75% of all radiant heat loss

4. Comprehensive design library of heat shields for steam traps

We have a heat shield design to match any field condition, custom or standard.

4. Easy Access to steam trap

Easy access to steam trap for crews to inspect, test, repair and replace. Heat Shields are easy to remove and reinstall.

Ask About Shannon Thermal Safety and energy efficient Products:

Shannon’s Removable Reusable Heat Shields for steam traps are an important part of your Personnel Protection program.

Why Specifying Shannon Insultech® Blanket Insulation systems is The BEST mechanical Insulation Solution to improve energy efficiency:

CAD Designed for exact fit & finish

CNC Produced for Accuracy and High Quality

Comprehensive Specifications to accommodate temperature and field condition

Each Blanket includes a Metal embossed ID plate with a QC code for indentification

Integral fasteners for easy off- easy on

Design standards tested to ASTM, UL and ISO

In summary, insulating facility steam system components with high quality removeable, reusable insulation blankets, with custom fit and integral fasteners not only improves energy efficiency but also enhances safety and prolongs the equipment’s lifespan. Consider it a cost-effective asset for better performance and reduced operational expenses.