Shannon Launches Hydronic Insulation Shield to Improve energy Efficiency in Hot and Chilled Water Systems

(2/2/26 AHR Las Vegas, NV )

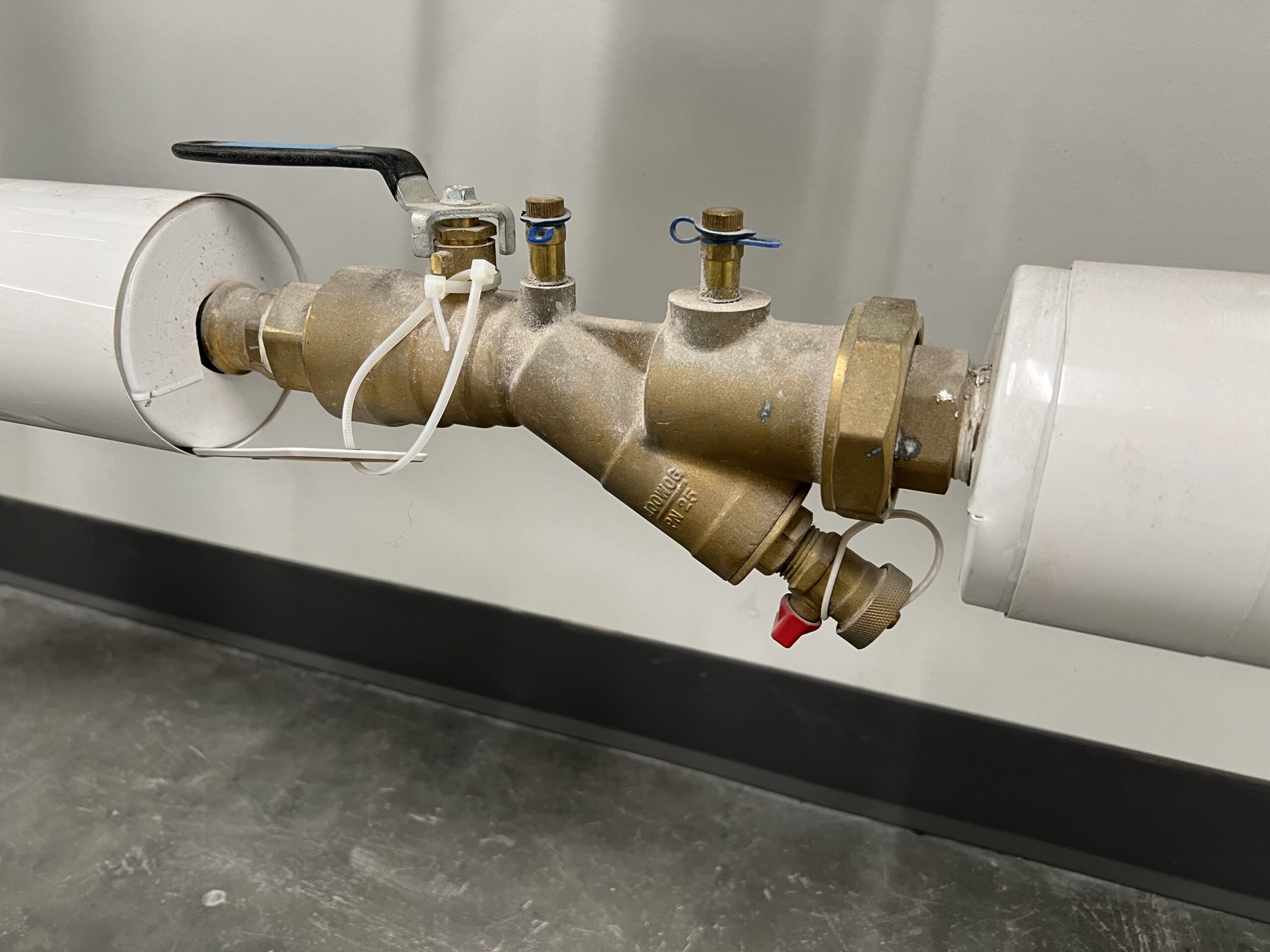

At AHR 2026, Shannon Global Energy Solutions launches, the new Shannon Hydronic Insulation Shield™, an innovation in hydronics. This reusable insulation solution is engineered to reduce radiant heat loss and improve energy efficiency across hot water and chilled water systems. Designed for valves and fittings operating at lower temperature ranges from 40°F to 190°F, the new system offers a cost-effective alternative to traditional hard insulation methods that are often damaged or discarded during routine maintenance.

Energy Savings with Easy Access

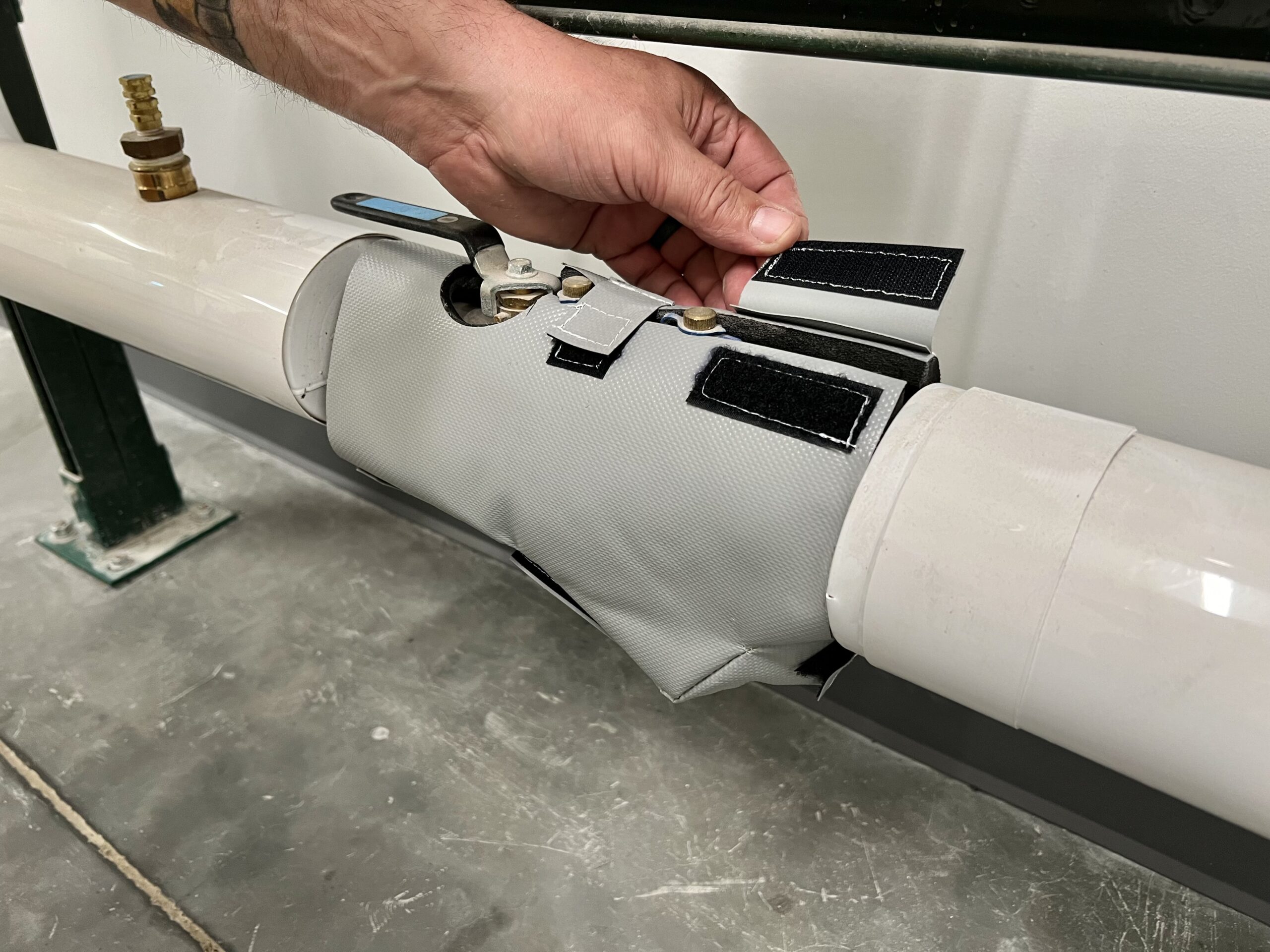

Uninsulated or bare system components can create significant radiant heat loss, driving up energy costs and reducing overall system performance. In many facilities, rigid insulation must be removed to gain access for inspection or repairs, frequently resulting in waste and permanently uninsulated components. The Shannon Hydronic Insulation Shield addresses these challenges by combining energy savings with easy access, allowing maintenance teams to remove and re-install insulation quickly without compromising system efficiency.

Field tested and proven, the Hydronic Insulation Shield is suitable for a wide range of hydronic applications, including hot water-to-hot water systems, steam-to-hot water systems, and chilled water systems.

This innovation in hydronics is also well suited for HVAC markets across commercial and industrial facilities, including manufacturing plants, hospitals, hotels, and hospitality environments where energy performance and reliability are critical.

Heat Loss reduction and reusability

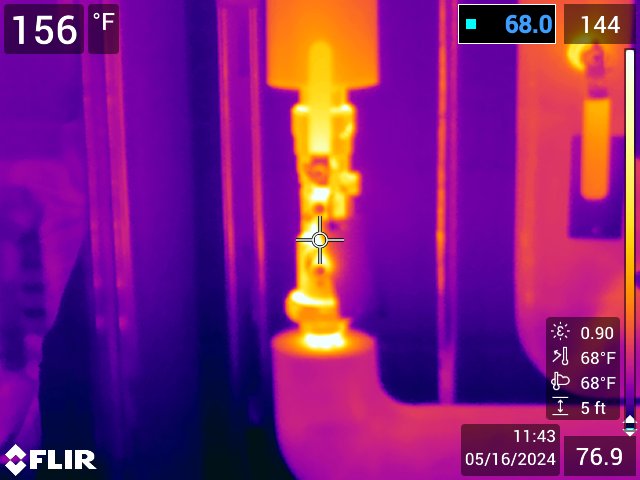

The system delivers measurable energy benefits, with typical surface temperature reductions of 80–85%, helping facilities lower energy consumption and improve personnel safety. Each insulation cover is engineered using CAD and CNC production, ensuring an exact fit and consistent finish. Integral Velcro fasteners allow for easy on/easy off installation, while a Mylar ID label on each piece simplifies identification, inspection, and maintenance planning. Because the insulation is reusable, it eliminates material waste commonly associated with traditional insulation removal.

SUSTAINABILITY

Sustainability is a core benefit of the Shannon Hydronic Insulation Shield. By reducing energy demand, the system supports CO2, NOx, and VOC emissions reduction while aligning with zero waste initiative goals.