Why is finding the Best University Energy Reduction Strategy Important?

Universities and college campuses use huge amounts of energy to run smoothly. The steam boiler system is a vital part of university campus operations. It also comprises a substantial percentage of the operating budget.

Steam boiler systems are crucial to the operation of universities in many ways

Here are six key reasons:

- Heating: Steam boilers provide heat to campus buildings, ensuring a comfortable environment for students and staff, especially during cold weather.

- Hot Water Supply: They supply hot water for dormitories, cafeterias, and other facilities, which is essential for daily activities like showering and cleaning .

- Food Preparation: University cafeterias rely on steam for cooking and cleaning, ensuring that meals are prepared safely and efficiently.

- Laundry Services: Steam boilers provide the hot water needed for laundry services, including washing machines used by students and for university linens.

- Sterilization: Laboratories and medical facilities on campus use steam for sterilizing equipment, which is vital for maintaining hygiene and safety standards.

- Support for Research: In research facilities, steam is often used in various experimental setups and processes, supporting the university’s academic and scientific endeavors.

A Systems Approach

These systems are integral to the smooth functioning of university campuses, supporting a wide range of activities and services.

Learn how to optimize the campus Steam Boiler system for energy efficiency to reduce costs, reduce emissions and achieve sustainability goals. Here is one of the simplest and best ways to reduce energy:

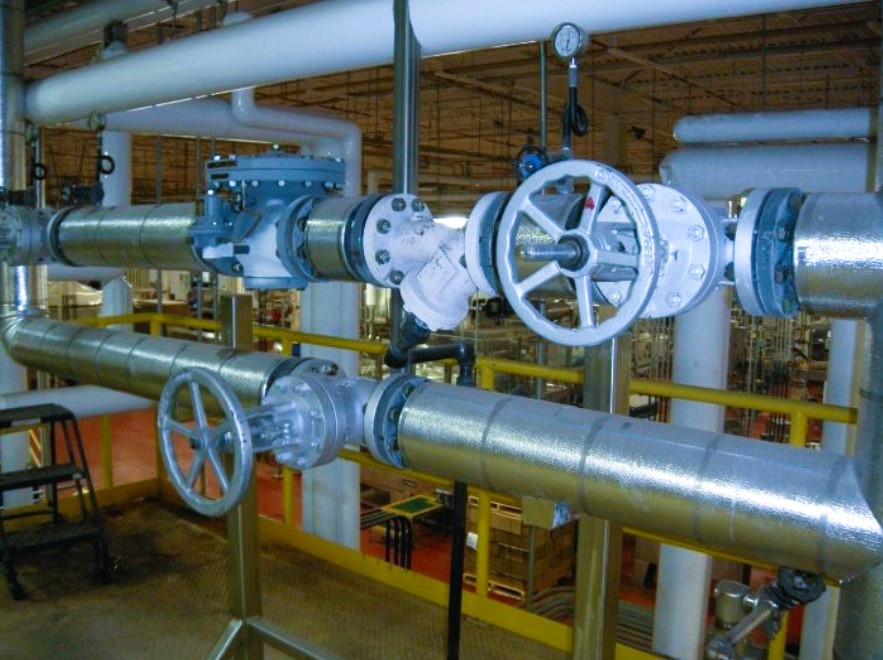

Walk your system. Note the bare control valves, PRV stations, strainers, flanges, heat exchangers, steam traps, condensate tanks, and other fittings not insulated because of complex geometry and need for frequent access. It doesn’t matter if your system is new or older, these uninsulated components represent a substantial heat loss in a typical system.

A Shannon Energy Survey:

Find the missing insulation in your system, like these valves and fittings shown here. How much do you have to gain by insulating bare components?

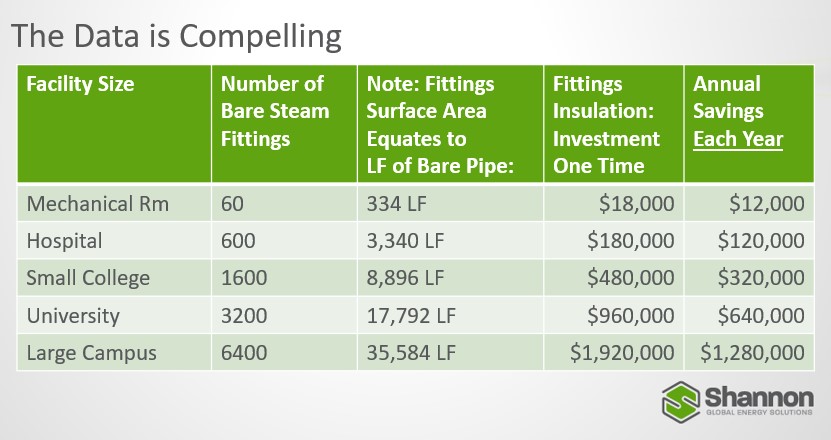

Look at the data below. Because of the complex geometry of valves and fittings, they have a lot of surface area. In fact, as shown in the table, the surface area of 60 typical fittings is approximately the same surface area as 334 linear feet of piping. And no one would leave 334 LF steam piping bare and uninsulated. Facilities have a lot to gain by insulating the valves and fittings in their systems with high quality reusable blanket insulation systems.

Over a 15-year expected life, the savings are stunning. Not only in BTUs and Therms savings and Reduced Emissions, but in financial savings, and reduced water consumption. Explore your facilities’ savings potential.

why Specifying Shannon Insultech® Blanket Insulation systems is The BEST mechanical Insulation Solution to improve energy efficiency:

CAD Designed for exact fit & finish

CNC Produced for Accuracy and High Quality

Comprehensive Specifications to accommodate temperature and field condition

Each Blanket includes a Metal embossed ID plate with a QC code for identification

Integral fasteners for easy off- easy on

Design standards tested to ASTM, UL and ISO

In summary, insulating facility steam system components with high quality removeable, reusable insulation blankets, with custom fit and integral fasteners not only improves energy efficiency but also enhances safety and prolongs the equipment’s lifespan. Consider it a cost-effective asset for better performance and reduced operational expenses.