Insulation JacketS for MRO Program Efficiency

Shannon Global Energy Solutions manufactures removable, reusable insulation blankets or jackets for equipment such as gate valves, globe valves, butterfly valves, steam traps, strainers, pumps, turbines, flanges, and other high-temperature or HVAC components. These products directly support MRO programs in several key ways:

1. Reduces Maintenance Time

Shannon blankets are designed to be easily removed and reinstalled without cutting, curing, or special tools.

This simplifies routine inspections and corrective maintenance because technicians can:

- Access equipment quickly

- Perform work without destroying insulation

- Restore insulation coverage immediately after repairs

Result: Faster maintenance cycles and less equipment downtime.

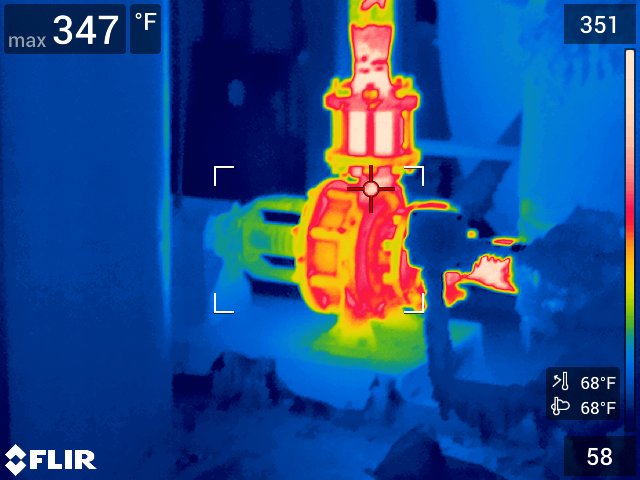

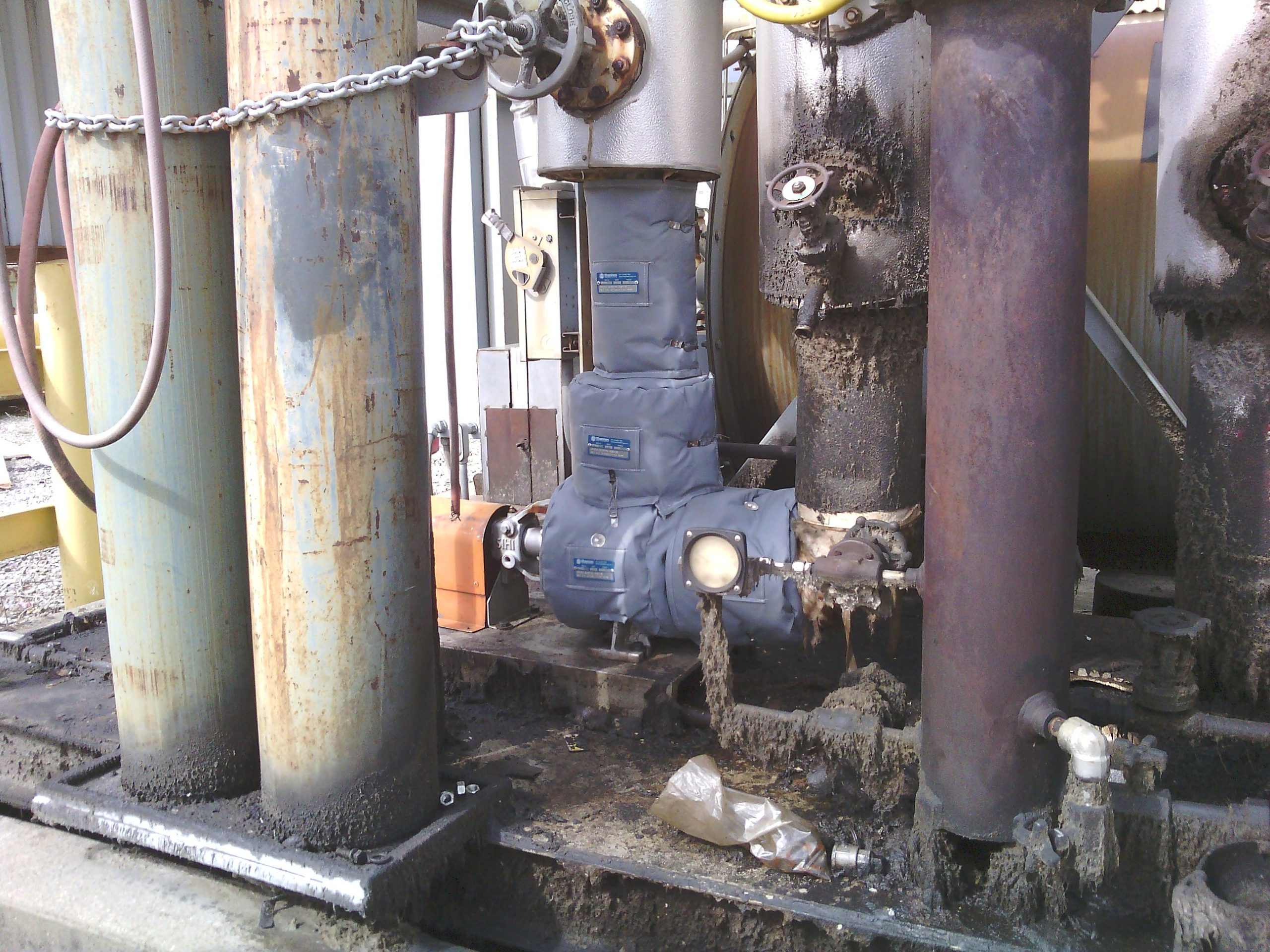

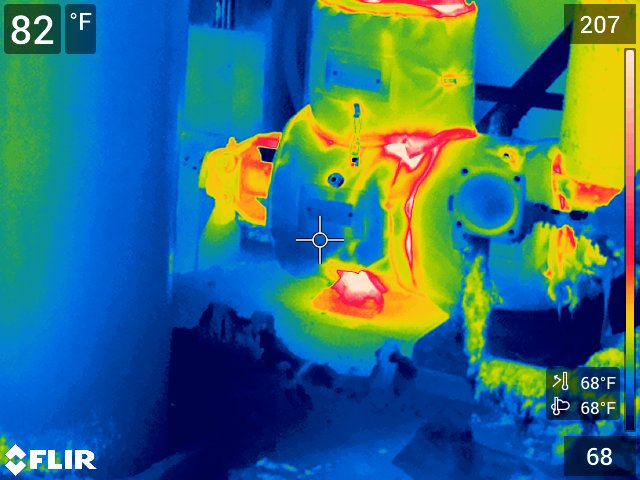

As shown below:

Hard Conventional Insulation gets removed and destroyed in the process. Involves extra Time and Labor as well as creating Waste. Leaves components Uninsulated.

2. Reusable Insulation Jackets Improve Safety for MRO Teams

The insulation blankets reduce surface temperatures and provide touch-safe coverage.

This helps MRO teams by:

- Preventing burns during inspection or repair

- Reducing the chance of accidental contact with hot surfaces

- Minimizing heat exposure in confined spaces

Result: A safer work environment with fewer incidents.

3. Cuts Energy Loss and Improves System Efficiency

Uninsulated components—especially in steam systems—are major sources of energy loss. Shannon blankets:

- Reduce heat loss on valves, flanges, and traps that cannot be permanently insulated

- Improve thermal efficiency of process equipment

- Lower a plant’s overall energy consumption and cost

Result: Energy savings that directly support reliability and cost-control goals in MRO.

4. Enhances Equipment Reliablity

Consistent insulation helps maintain stable operating temperatures.

Benefits include:

- Protecting components from thermal stress

- Preventing condensation or corrosion under insulation (CUI)

- Minimizing wear on sensitive equipment

Result: Fewer maintenance issues and longer asset life.

5. Supports Predictable MRO Planning

Because Shannon blankets are reusable and labeled for easy identification, they contribute to:

- Standardized maintenance procedures

- Quicker troubleshooting

- Better equipment documentation

- More predictable service intervals

Result: MRO teams can plan tasks more efficiently and avoid unexpected delays.

6. Reduces Waste and Environmental Impact

Conventional hard insulation must be cut off and discarded during repairs. Shannon’s reusable blankets eliminate this recurring waste.

Result: Lower material costs and improved sustainability metrics—important for modern MRO programs.

MRO- Achieve Operational Resilience and Long-Term Savings

Maintenance, Repair and Operations

Shannon Global Energy Solutions transforms MRO from a reactive cost center into a strategic advantage. By combining reusable insulation technology with a focus on safety, efficiency, and sustainability, Shannon helps companies achieve operational goals. For industries where downtime is costly and safety is paramount, Shannon’s engineered insulation systems are a proven solution to modern MRO challenges.

Summary

Shannon Global Energy Solutions plays a highly valuable role in a company’s MRO program by:

- Speeding up maintenance work

- Improving worker safety

- Reducing energy losses

- Boosting equipment reliability

- Supporting efficient MRO planning

- Lowering waste and costs

Why Specifying Shannon Insultech® Blanket Insulation systems is The BEST mechanical Insulation Solution to improve energy efficiency:

CAD Designed for exact fit & finish

CNC Produced for Accuracy and High Quality

Comprehensive Specifications to accommodate temperature and field condition

Each Blanket includes a Metal embossed ID plate with a QC code for indentification

Integral fasteners for easy off- easy on

Design standards tested to ASTM, UL and ISO

In summary, insulating facility steam system components with high quality removeable, reusable insulation blankets, with custom fit and integral fasteners not only improves energy efficiency but also enhances safety and prolongs the equipment’s lifespan. Consider it a cost-effective asset for better performance and reduced operational expenses.