Insulation systems for asphalt plant efficiency

Sustainable practices in asphalt production focus on reducing energy consumption, lowering costs, and minimizing environmental impact. Key strategies include insulation, plant management, and addressing production processes to improve efficiency and sustainability.

Insulate Plant Components

Insulation of plant components, such as tanks, dryer drums, silos, and piping, will reduce heat loss to the environment and thereby reduce production cost.

Benefits include reductions in energy needed for production, conservation of natural resources, reduction of GHG emissions, and safer worker exposure conditions.

Plant Management

It’s important to recognize that investments in insulation for reducing energy consumption will be recovered in one to two years, after which annual savings continue at no cost for life of the insulation asset.

Measurement and Verification

Shannon can provide an M & V report to show that expected results were obtained.

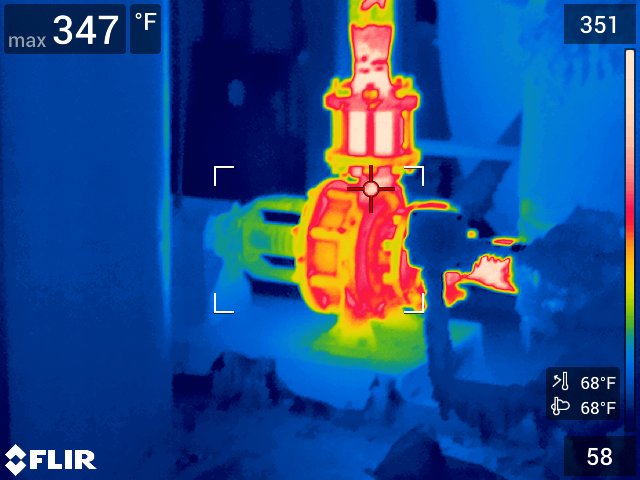

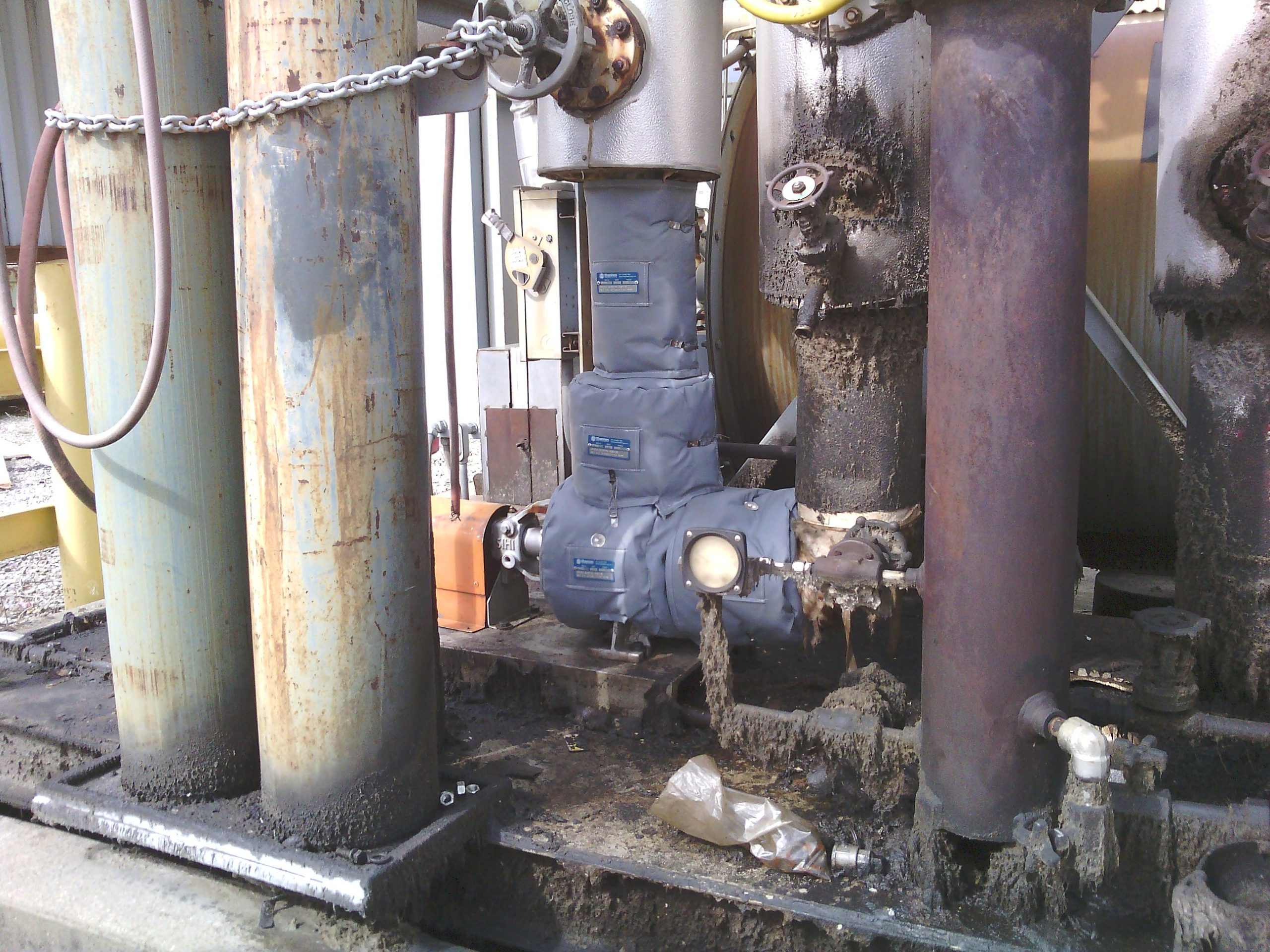

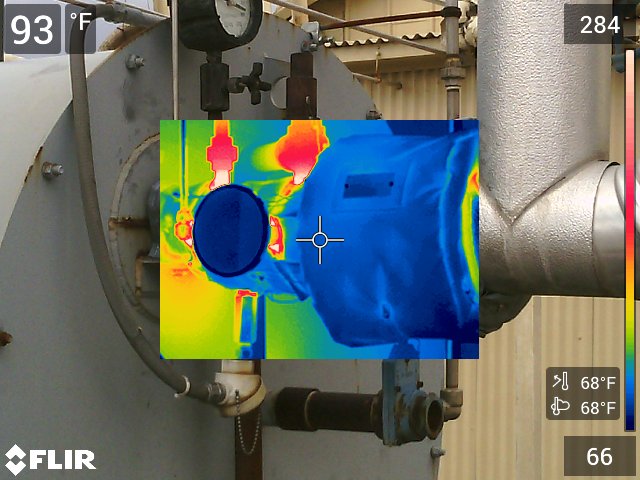

Shown are the Thermographic images of an Asphalt Pump Before (bare) and After with a Shannon Thermal Insulation Blanket:

Energy Efficiency in Asphalt Production Processes

Aggregate Handling, Drying, and Heating

Moisture content in aggregates significantly affects drying energy; a 1% increase in moisture can raise energy needs by 10%. Covering stockpiles, paving and sloping storage areas for drainage, orienting stockpiles to sunlight and wind, and managing stockpile height reduce moisture and drying energy. Optimizing burner efficiency with regular tuning, maintaining insulation on drying drums, and improving flighting for even aggregate distribution reduce fuel use. Warm-mix asphalt technologies reduce mix temperatures by 10-100°F, saving up to 55% energy and lowering emissions. Alternative fuels such as recycled oils and electric equipment also offer savings. Production optimization to reduce stops and restarts further saves energy .

Asphalt Cement Heating AND INSULATION

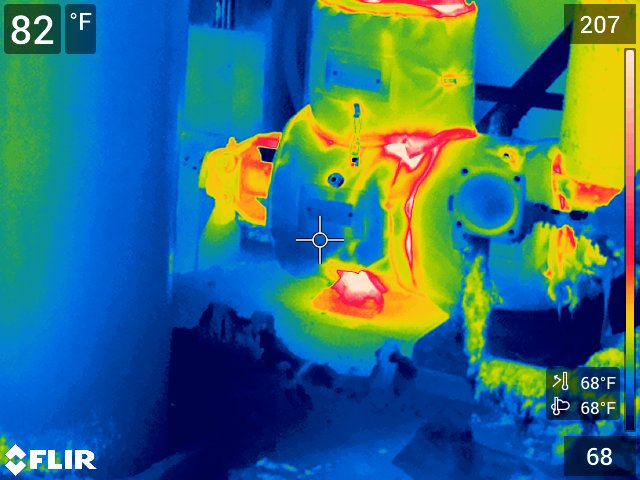

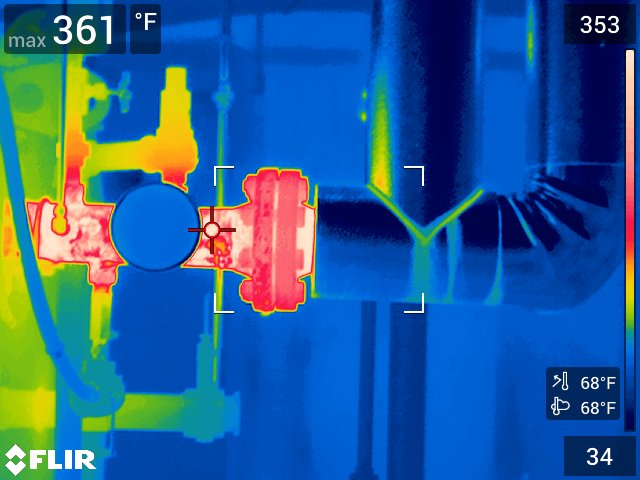

Hot-oil heaters heat asphalt binder and mixture silos. Efficiency improvements include selecting high-efficiency heaters, adding heat exchangers to recover exhaust heat, switching to electric heaters. And insulating piping, flanges, pumps, valves and storage tanks. Proper insulation of heaters, heat exchangers drastically reduces heat loss and energy consumption. Complex Surfaces can be Insulated with Fitted Thermal Insulation Blankets engineered and manufactured to verified and tested specifications for temperature, application and conditions.

Shown are Thermographic images of an Asphalt Heater, Before (bare) and After fitted with a Shannon Thermal Insulation Blanket.

Summary

Implementing energy efficiency measures in asphalt mixture production reduces costs, stabilizes earnings amid energy price volatility, and supports environmental goals. Combining strategic energy management with proven technologies and practices is essential for ongoing improvements. Companies should assess the feasibility and benefits of these measures tailored to their facilities .

Ask About A Shannon Energy Survey:

Since 1988, Shannon Global Energy Solutions has saved more than 400 Million Therms and 3.1 Million Metric Ton of CO2 using easy to use and long-lasting Reusable Thermal Insulation blankets providing 50-75% Energy Reduction and reduced fuel costs and GHG Emissions. Shannon is proud to be a National Grid ProNet Award Winning Partner and Con Ed Trade Ally Partner since 2022.

Whether you call them Valve Jackets, Blankets or Covers, Shannon’s Removable Reusable Insulation Blankets for valves are an important part of your energy efficiency and sustainability program.

Why Specifying Shannon Insultech® Blanket Insulation systems is The BEST mechanical Insulation Solution to improve energy efficiency:

CAD Designed for exact fit & finish

CNC Produced for Accuracy and High Quality

Comprehensive Specifications to accommodate temperature and field condition

Each Blanket includes a Metal embossed ID plate with a QC code for indentification

Integral fasteners for easy off- easy on

Design standards tested to ASTM, UL and ISO

In summary, insulating facility steam system components with high quality removeable, reusable insulation blankets, with custom fit and integral fasteners not only improves energy efficiency but also enhances safety and prolongs the equipment’s lifespan. Consider it a cost-effective asset for better performance and reduced operational expenses.