Reduce Ambient Temp in Mechanical and Boiler Rooms

When it comes to reusable insulation, there are three major benefits: energy savings, cooling, and worker safety. While energy savings are often top of mind when considering investing in insulation blankets, the mitigating effects insulation can have on hot industrial elements can be just as impactful.

Many facilities, from food processing plants to universities, have extremely hot components out in the open, posing a direct safety hazard to those who work around them.

“Typically, it’s an exposure hazard,” said Peter Kessell, Outside Sales Engineer at Calpacific Equipment Company. “There’s hot surfaces on steam or extruder lines, where the operators are working right in that area, and they have to walk past a surface that can be 220 degrees or 370 degrees.”

A common example of this is a globe valve, often found on large steam mains.

“A lot of times, they’re right at upper-body level,” Kessell said. “You have enough space to get by, but you’re still moving past a surface that’s 220 degrees Fahrenheit.”

High Temperatures

Such high temperatures radiating out in the workplace leads to the second concern insulation can address: cooling. In a confined space, hot elements can heat a room to uncomfortable levels that affect worker safety. This can often be found in mechanical and boiler rooms at universities and hospitals, places without the space to spread out these hot components.

“At a local university, their mechanical room could get up to 120 degrees [Fahrenheit],” recalled Kessell. “After the insulation was installed, there was about a 20-degree [Fahrenheit] drop, very noticeable.”

Reusable insulation blankets, like those manufactured by Shannon Global Energy Solutions, are one of the best ways to address these concerns. Unusually shaped components are best insulated with a custom blanket, to ensure a perfect fit.

“The Shannon insulation blankets are a very good fit for the odd-sized stuff, for globe valves, for condensate return systems, for the stuff you need a custom fit,” said Kessell.

Initial Safety Training and Refresher Training

Making sure employees have proper training, to cover hazards and a baseline overview of OSHA standards, before starting a job is important. Then provide a more site-specific, job-specific training to include in-depth safety procedures with any machinery or materials they will become involved with. Ongoing refresher training should keep employees current on standards and should ensure safety procedures are top-of-mind.

Hazard Communication

Color codes, labels, or signs to warn employees of potential hazards are an employer requirement under the OSH Act, and these vital pieces of Hazard Communication are extremely important in burn prevention. Workers should be trained in how to recognize symbols and other hazard communication codes, and communication standards should be used to identify hazards in a consistent and easily recognizable way.

Preventing Thermal Contact Burns

Properly designed and manufactured Thermal Insulation Blankets are a valuable worker safety measure. Insulation blankets will provide an insulated barrier between the high temperature equipment and personnel, and thereby help mitigate radiant heat from hot equipment surfaces.

Utilizing a system of thermal blanket insulation will also lower the ambient temperature in mechanical rooms, creating a more comfortable work environment and easing issues of heat stress.

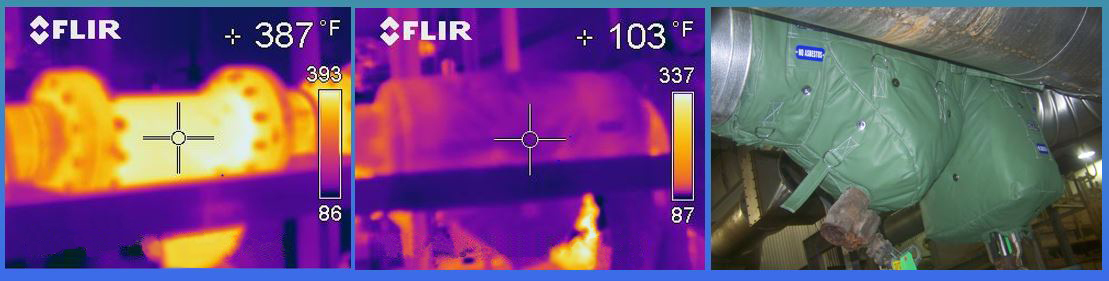

Take for instance, a gate valve or other equipment that has a bare radiant heat temperature of 387° F . With installation of a Shannon blanket, correct for the condition, the radiant temperature can be reduced to under 105° F.

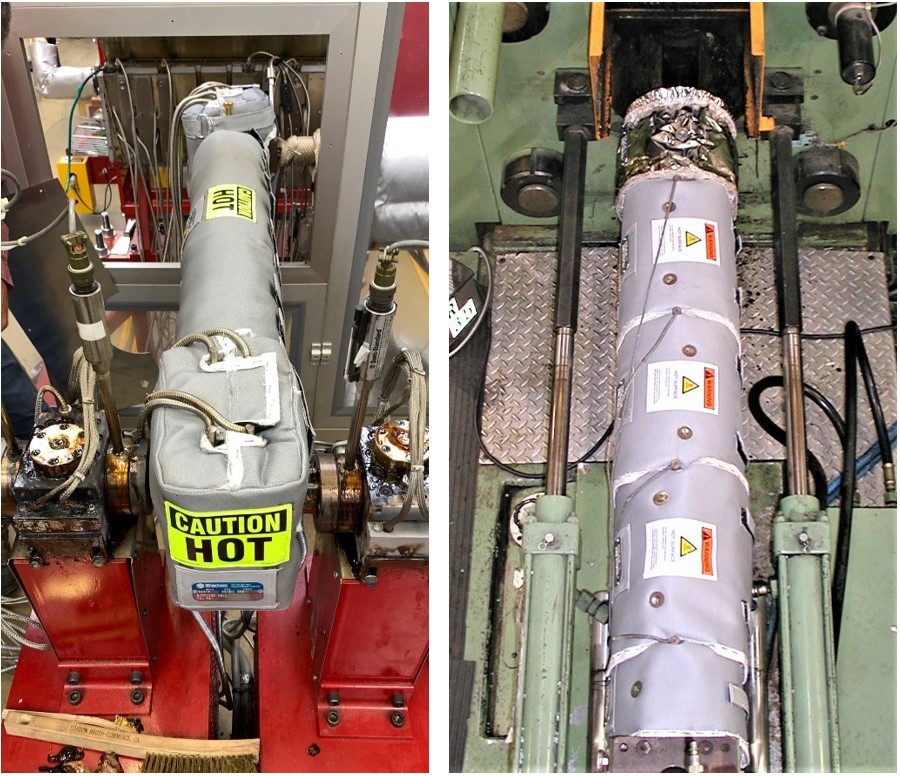

More examples of hot equipment insulated with a Shannon GES solution.

Shown are an insulated Tire Press at a Tire Manufacturer and an insulated Legger Buck Press at a Commercial Laundry Services firm. All Shannon Insulation blankets specs are designed and produced for the customer’s equipment and operating condition. All are removable and reusable for easy access to equipment for inspection and maintenance.

Utilizing a system of thermal blanket insulation will also lower the ambient temperature in mechanical rooms, creating a more comfortable work environment and easing issues of heat stress.

Shannon Thermal Blankets can also be designed with hazard communication labels to inform employees about the equipment beneath.

Contact us for more information about Shannon Thermal Blanket insulation for your application.