By: Frank Kovacs, CEO, Shannon Global Energy Solutions, Inc.

My vacation trip to Ireland this past week included the grand tour of a legacy distillery. Established in 1757, this distillery included both waterpower (Early Years) and steam. It was enlightening to see the great history and the success of integrating steam into the production process of Irish Whiskey. We sometimes forget to think about just how complex, some processes can be, and we take for granted, the value of the process, to produce the resulting products we use every day. Great whiskey production is a science that requires the correct inputs to achieve the expected outcome. It also required steam heat!

Part of the tour allowed photos to be taken and one photo that caught my mind was both Deaerator Tanks, Piping, Valves, and a large capacity Steam Trap, leading up to the DA Tank, all left uninsulated.

This hardware dates to the 1930’s, so to see this was enlightening. A steam system still in use to this date, although slightly upgraded, shows that the principles of steam have not changed, it’s the hardware that has changed.

Like steam principles, the use of insulation principles has not changed. Look at this system, not a single fiber of insulation placed anywhere. Bare surface conditions are everywhere in an outdoor condition. I was surprised/shocked to see a lack of insulation on the modern process as well. Minimal insulation, namely personnel protection, but no significant application of insulation materials to improve efficiency.

Keep in mind, Europe is facing an energy crisis like never before. Energy costs have increased 300% to 400% in just one year, so any opportunity to reduce fuel or energy should be considered. Radiant heat is wasted BTUs, and every BTU lost is expensive.

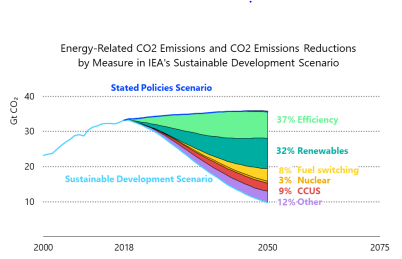

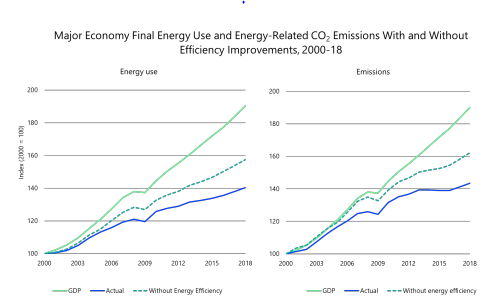

The global commission for urgent action on efficiency lists recommendations on sustainability initiatives. The top priority and the most impactful measure on savings is Energy Efficiency at 37%. Renewables trail at 32% and then a host of other options, well below these two strategies. The point being, Energy Efficiency is the lost leader, the commonsense approach to improved system performance and an impactful sustainable cost effective and tangible benefit. It simply makes sense to insulate.

“Energy Conservation Through Insulation”, the simple practice of insulating the uninsulated, becomes the focal point of this topic, insulating bare surfaces and capturing radiant heat loss. The best part of this subject is our ability to measure the impact. We can determine the measured performance. Keep in mind, a BTU saved is CO2 saved, it’s that simple!

The current discussion centers on the cost $ per Ton of CO2. So, what’s the cost to generate 1 each ton of CO2 reduction, which determines the most productive, effective use of investment dollars for sustainability. Each technology represents a different cost per ton of CO2 reduction, and it varies from carbon capture at $800 to insulation at $300/Ton. Insulation is one example of a highly effective investment with immediate outcomes. Keep in mind, we assume a 15-year continuous performance, year after year and the cost of ownership is zero.

Just looking at these DA Tanks, some piping and steam fitting components (Steam Traps, Valves), you get the feel that heat loss and energy savings was never a consideration. That steam quality and efficiency were never considered. Insulation has a direct impact on performance as well as steam quality.

But what if these factors were considered and what if the system efficiency was drastically improved because of “Best Practices” of reusable removable insulation materials. We can guess at some figures here on performance, assuming surface geometry, operating temperature, pipe size and lengths, we can estimate or benchmark performance savings. Its easy to see the benefit.

The total system measure is calculated as follows:

4,838mm BTU of wasted energy per Year

44,069 Therms of energy “saved” per year

@ $30.00 / mm BTU of steam cost: $132,177.00 per year in savings or $ 1.9 Million @ 15 Yrs

@ $90.00 / mm BTU of steam cost: $396,533.00 per year in savings or $ 5.9 Million @ 15 Yrs

The total system CO2 Reduction (Tons/Year) is calculated as follows:

Burning Natural Gas: 257.98 tons CO2 per Year Savings (15 Year Impact: 3,869 tons CO2)

- Cost per Ton = $ 469 / Ton CO2

Burning #6 Fuel Oil: 393.53 tons CO2 per Year Savings (15 Year Impact: 5,902 tons CO2)

- Cost per Ton CO2 = $307.00 / Ton CO2

Probably the most compelling measure is simple payback period:

- 9 Months @ $30.00/mm BTU Steam Cost

- 3 Months @ $90.00/mm BTU Steam Cost

It’s not hard to see the benefits of a simple reusable removable blanket insulation solution. Whether you are using steam for heat or processing, measure the benefit and the decision is even more compelling. Insulate the uninsulated. Take the time to identify the potential and then call in an expert to define the potential scope and performance. Energy surveys that itemize these potential opportunities will clarify the potential and give to you the reassurance that insulating should be your first line of defense in combating energy costs. The added benefits from CO2 and NOx reduction are the added drivers in the decision. Rethink insulation as a primary focus on your sustainability initiative. Invest your sustainability dollars wisely.