“What has changed has been the adoption of reusable blanket systems on components and complex surfaces that otherwise would be left uninsulated,” said Frank Kovacs, CEO of Shannon.

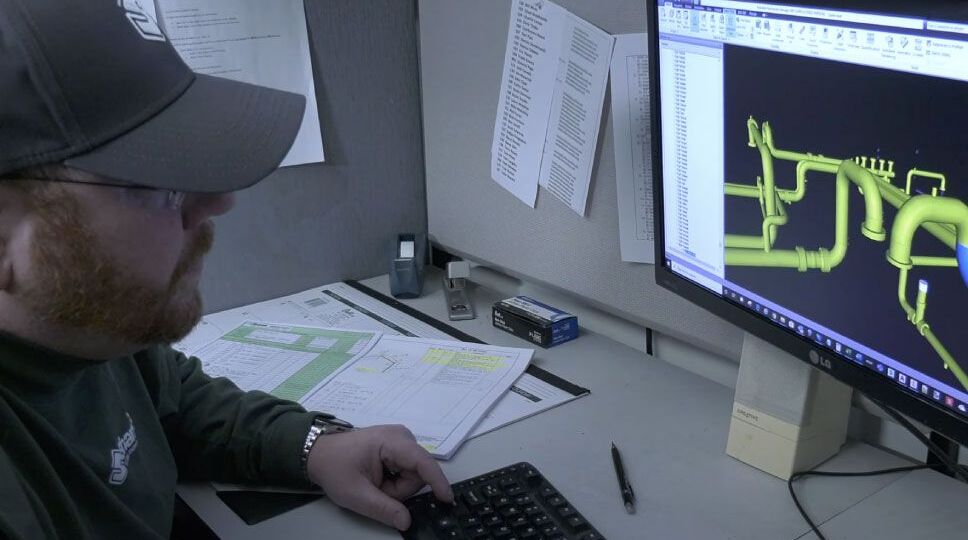

The development of specifications and new surveying technologies, including thermographic imaging, alongside sophisticated CAD drafting software enable the insulation of components that would otherwise remain bare. Small components and systems with complex geometry can have quality, reusable blankets specifically designed to fit their unique contours through these advances in design.

“What you’ve got now in the insulation industry is this evolution of design, created by application and performance, that is now very specific,” said Kovacs.

CAD drafting also allows for the standardization of reusable blanket specifications and design for different components. Take, for instance, a liquid chiller. If a liquid chiller was previously designed with CAD software, insulation industry designers can reuse that file. This ensures a near perfect fit on the component and assures the customer of uniform performance standards, for both thermal and noise reduction.

“A liquid chiller may run noisy, now there’s an opportunity to treat the chiller with an acoustic blanket solution tested under very specific conditions that relates to noise reduction expectations,” added Kovacs.

Advances in blanket testing further ensures high standards of performance and allows for accurate prediction of service life and design specifications.

“There’s an AHRI-575 test method that’s used to accommodate a liquid chiller application, and under this test method, we can predict or define the value of the blanket system installed,” said Kovacs.

These changes in insulation design and procedures have resulted in dramatic improvements to the quality and longevity of reusable insulation blanket systems.