How to determine Quality in Blanket Insulation

To determine Quality in blanket insulation for HVAC, steam heating, and steam processing, you should consider the following factors: Engineering, Design, Construction and Performance

- Engineering: The blanket should be made of high-quality materials that are designed to the specific application, conditions, and environment in which it will be used.

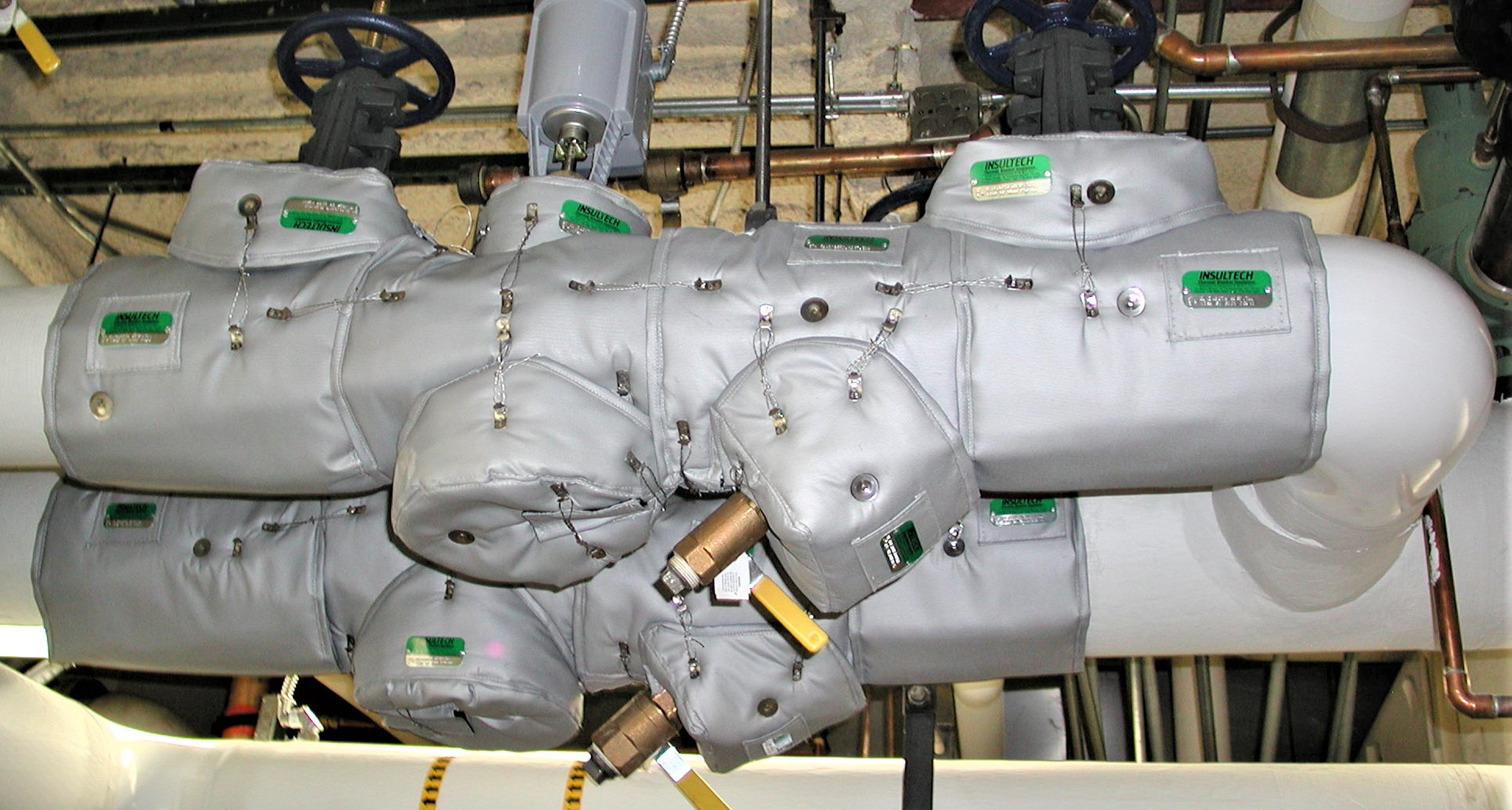

- Design: The blanket should fit snugly to the equipment it is insulating, as well as to the other blankets or conventional pipe insulation, without any unnecessary gaps or spaces.

- Construction: The blanket should be well-constructed with double-sewn seams and durable stitching. It should also have integral fasteners that are easy to use, maintain and provide ease of installation.

- Performance: To conserve energy, the blanket should be designed specifically for the intended application and manufactured with quality control processes. The blanket’s thermal properties must be tested to ASTM standards. These values are to be used in the Energy Savings calculations.

Why is Quality Important

1. Energy-Efficient Performance

Preventing radiant heat loss is the main goal of a thermal blanket insulation system.

To capture radiant heat, insulation must be comprised of the correct materials and must fit accurately to the equipment in the system without gaps or spaces on or between components.

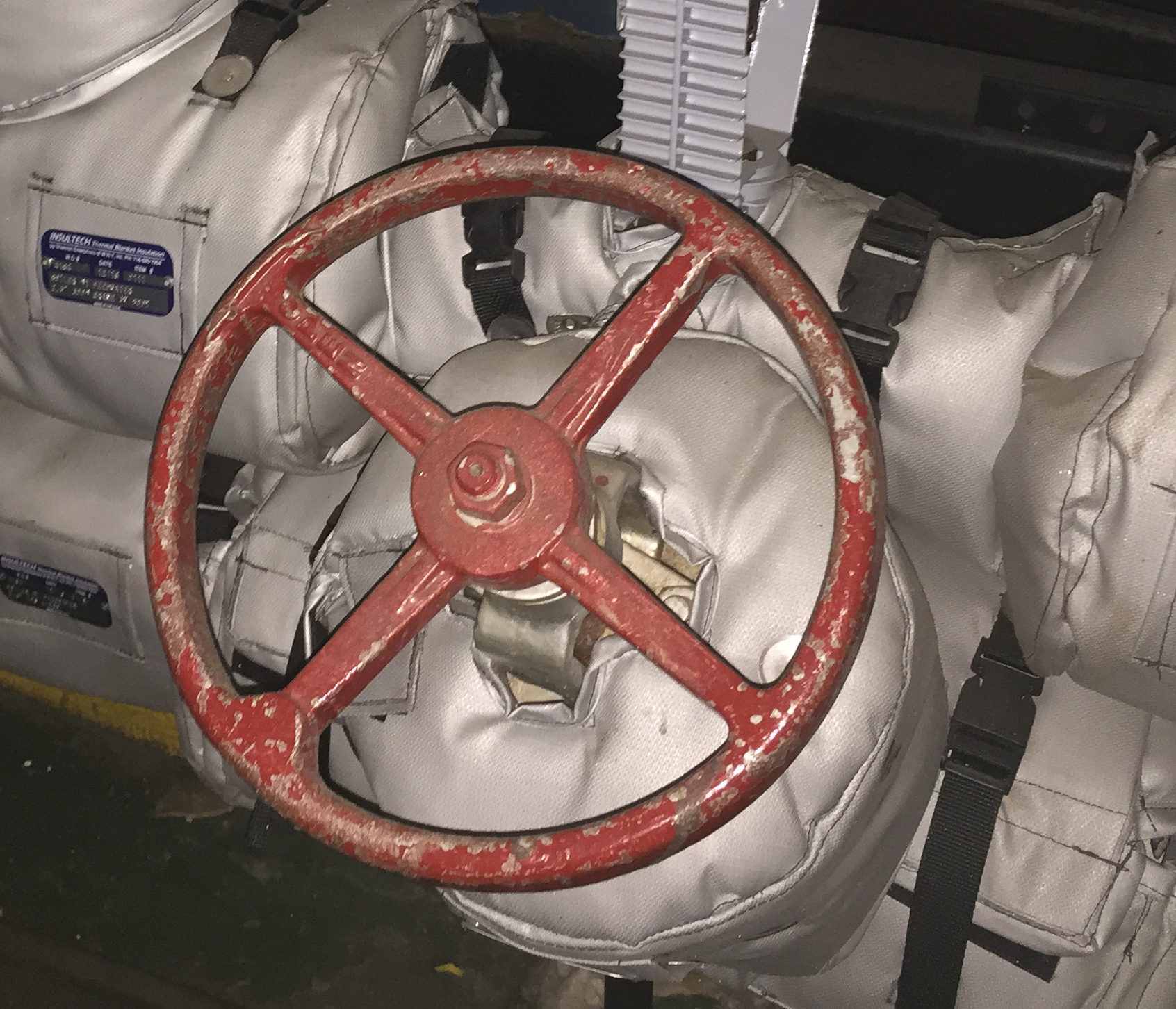

Poorly-made or ill-fitting blankets allow heat to escape. Some manufacturers will use drawstring wind-flaps in an indoor application, to hide the fact that there are gaps between blankets and leaving areas uninsulated.

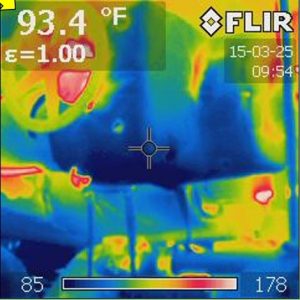

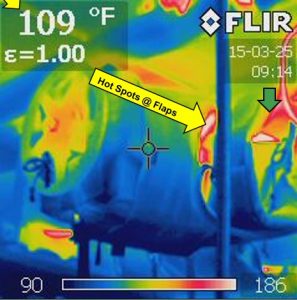

These manufacturers will not have designed their blankets to ensure their blankets achieve the energy savings claimed. An energy performance survey created by a high-quality manufacturer with high standards will not be achieved by a low-grade substitute. High-quality blanket manufacturers can verify their energy performance, backed by ASTM testing and calculations.

2. Reusability

All insulation is removable, the key is reusability. A quality insulation blanket will be one that is easy to remove and correctly reinstall after inspection or maintenance of underlying equipment. A quality insulation system has blankets that fit equipment and fit to each other, precisely (without gaps or uninsulated flaps masking gaps). Precise fit and integral fasteners ensure a blanket system that maintenance staff can quickly put into their correct positions when reinstalling them. Blankets that are not easy to put back into place will be reinstalled haphazardly or not at all, defeating the purpose.

Integral fasteners and a precise fit allow for reinstallation in less time. The probability of a blanket being reinstalled by staff increases as the ease and speed of reinstallation increases.

3. Accurate Design Specifications

Experienced engineers and designers utilize correct materials and construction for the client application and environment for which the Insulation Blankets will be used. Every material, from the interior insulation layers to the outside jacketing, to the stitching and fasteners are engineered for the specific use and environment. There is no universal blanket specification because no one spec fits all situations. With a quality manufacturer, engineering and testing standards assure customers that the blankets will perform as stated.

4. Long Service Life

Double-sewn, lock stitch construction, high quality jacketing and inner insulation materials, and durable integral fasteners are necessary for long life. With quality engineering, design and construction that is correct for the application and condition, you can expect a 15-year service life. This long service life provides long-term savings on energy costs.

5. Payback

The initial investment in quality insulation blankets can be paid back in a relatively short period of time through energy savings. An accurate energy savings survey is necessary to determine true savings and therefore true payback periods. With a quality blanket system, you can achieve a 12 – 24-month payback period. After the payback period, your savings go back into your budget. Over the course of 15 years this is a significant amount of return.

Quality Shannon Blanket

Low Grade Blanket with Gaps and Hot Spots

Average surface Temp reduction (15.6F) and hot spot reductions.

A 6.5% difference on performance!

6. Sustainability

The #1 sustainability measure is energy efficiency. With energy efficiency comes lower energy use and costs as well as lower CO2/ NOx/ VOCs emissions. And for steam systems, reduced water usage can be achieved. Measurement and verification can show the results.

By investing in a quality blanket insulation system, you can improve the energy efficiency of your HVAC, steam heating, or steam processing system, save money on energy costs, and reduce your environmental impact.