According to the U.S. Green Building Council’s website, “LEED (Leadership in Energy and Environmental Design) is the most widely used green building rating system in the world.” The USGBC also notes, “A 2014 UC Berkeley study found that by building to LEED standards, buildings contributed 50 percent fewer GHGs than conventionally constructed buildings due to water consumption, 48 percent fewer GHGs due to solid waste and 5 percent fewer GHGs due to transportation.”

All facility owners may not be able to adapt or build to LEED standards immediately. But facility managers can still provide their workers with healthy, safe, energy-efficient and sustainable buildings.

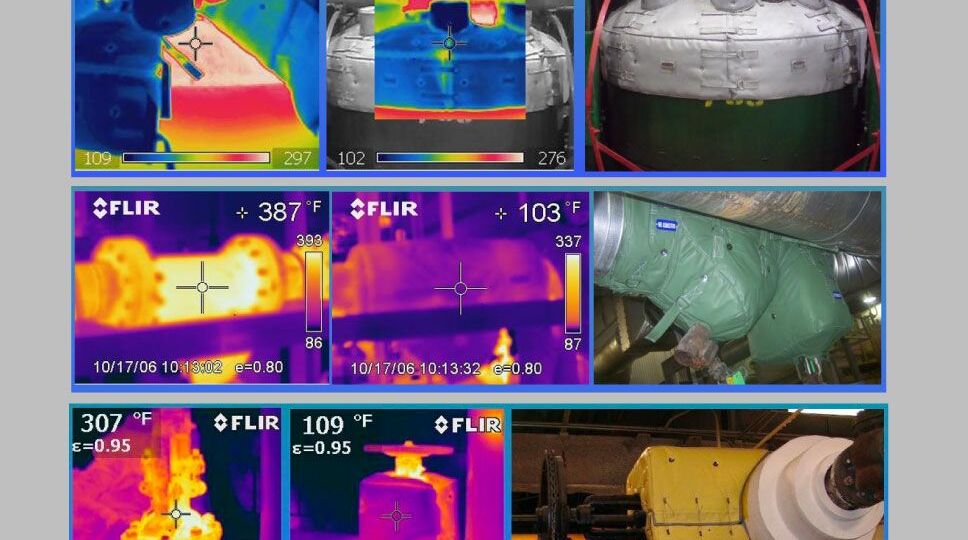

Industrial-strength removable and reusable insulation produced by Shannon Global Energy Solutions reduces energy cost, which makes heating and cooling efficient. Customers around the world have trusted Shannon’s name in insulation since 1988. Shannon GES prides itself on manufacturing removable and reusable insulation for facilities and providing workplace and environmental safety solutions. Shannon’s high-quality products are safe and affordable, and Shannon offers a wide range of insulation solutions that are tailored to meet the needs and budgets of different facility owners.

LEED is based on principles that promote sustainable building practices, including minimizing potential health risks for occupants, reducing environmental impacts, and maximizing energy efficiency. Products like Shannon’s removable and reusable thermal insulation significantly reduce the temperature inside boiler rooms, making for a safer environment for maintenance teams. Shannon’s removable and reusable acoustic insulation reduces noise from industrial components by up to 6dBA or more depending on the application. So acoustic insulation also makes for a safer, healthier environment. A well-insulated system, which includes removable and reusable insulation for piping and components like valves and steam traps, reduces a facility owner’s cost of energy. That, in turn, reduces the amount of greenhouse gas and money spent heating and cooling a facility.

When the USGBC released LEED v4.1 in 2019, the council said the latest version of the standard would “make LEED the first green performance standard for buildings, communities and cities.”

Like the USGBC’s LEED standards, Shannon has long adhered to defining standards for its removable and reusable insulation. Shannon has advocated that the insulation industry adopt the same strict standards that its President and CEO Frank Kovacs created more than 30 years ago and has followed ever since. These include the Construction Specification Institute-3 Part and 10 Part specification formats to apply a comprehensive standard. Shannon also tests its insulation blanket designs to ASTM, ISO and UL standards.

Why do standards matter?

For adherents of LEED, standards ensure:

- LEED remains the global leadership standard for green buildings

- Improved performance throughout the life of buildings

- Building owners can track progress toward environmental, social, and governance goals

For Shannon, creating and adhering to standards:

- Ensures that when customers select a blanket design, they’re getting the proper blanket design based on an established specification. For instance, each application could pose a different condition in the field, which would call for a different design.

- Assures customers that the blanket, safety shield, or other Shannon solution will perform as designed for the product’s life – often up to 15 years or more.

Just as a LEED-certified project focuses on sustainability, Shannon’s solutions are centered around sustainability and built to last for decades. For example, Shannon’s solutions help facility managers recover waste heat radiating from boilers as mentioned above. When facility managers leave boilers uninsulated, there’s excessive heat for workers in these boiler rooms, which poses a risk of burns and/or dehydration. But the equipment is also at risk because an uninsulated boiler can lead to refractory damage, which can cause heat to dissipate from the boiler walls. That, in turn, drives up the cost to generate steam for other industrial processes and electricity.

By installing a system of reusable thermal insulation blankets, it’s not uncommon for a facility owner to save tens of thousands of British thermal units per hour. Along with Btu savings, maintenance engineers will see temperatures significantly drop after installing reusable thermal insulation. One of Shannon’s many projects saw managers experience a temperature drop of several hundred degrees Fahrenheit within their boiler area. Without insulation covering an operating boiler, these areas are impossible to stand in due to high temperature and are a safety concern.

Often, when insulation comes off a piece of machinery, it never goes back on because the design is flawed; the product’s manufacturer doesn’t design to a standard of quality. Manufacturers who don’t adhere to design standards fail to consider ways to make self-contained insulation easy to remove and reinstall with features like integral fasteners. In addition, most manufacturers don’t design thermal insulation properly for reuse. When thermal insulation is engineered correctly, it ensures sustainability, safety and prevents heat loss; and it is easy for workers to remove and replace, in minutes.

LEED is a framework for designing and constructing buildings that reduce greenhouse gas and draw on the use of fewer resources, which support human health. As companies and communities increasingly look to LEED certification, facility managers should examine how removable and reusable insulation can also help them efficiently meet corporate and institutional ESG goals and reporting. This is how Shannon delivers energy conservation through insulation.