Preventing Burns in the Workplace

Thermal Burns are a common workplace injury that can cause serious harm to employees. According to the U.S. Bureau of Labor Statistics (BLS) in 2020, 11,840 workers sustained thermal burns that were severe enough to keep them out of work.

Thermal burns are defined as a category of burns caused by:

- Hot liquids (Scalding)

- Open flames

- Hot object or hot surface (Contact Burns)

Preventing thermal burns should be a top priority for employers, as these incidents can lead to serious injury, lost productivity, and decreased morale. Research data shows us that an estimated 20-30% of all hospitalizations due to burn injuries, result from workplace exposures.

In this blog post, we will explore some effective strategies for preventing thermal burns in the workplace and creating a safe and healthy work environment for all employees. According to the OSHA article “Preventing Workplace Burns”, under the Occupational Safety and Health Law (OSH), employers have a responsibility to provide a safe workplace. When it comes to burns, here are a few ways employers can help to provide safe workplaces.

Initial Safety Training and Refresher Training

Making sure employees have proper training, to cover hazards and a baseline overview of OSHA standards, before starting a job is important. Then provide a more site-specific, job-specific training to include in-depth safety procedures with any machinery or materials they will become involved with. Ongoing refresher training should keep employees current on standards and should ensure safety procedures are top-of-mind.

Hazard Communication

Color codes, labels, or signs to warn employees of potential hazards are an employer requirement under the OSH Act, and these vital pieces of Hazard Communication are extremely important in burn prevention. Workers should be trained in how to recognize symbols and other hazard communication codes, and communication standards should be used to identify hazards in a consistent and easily recognizable way.

Preventing Thermal Contact Burns

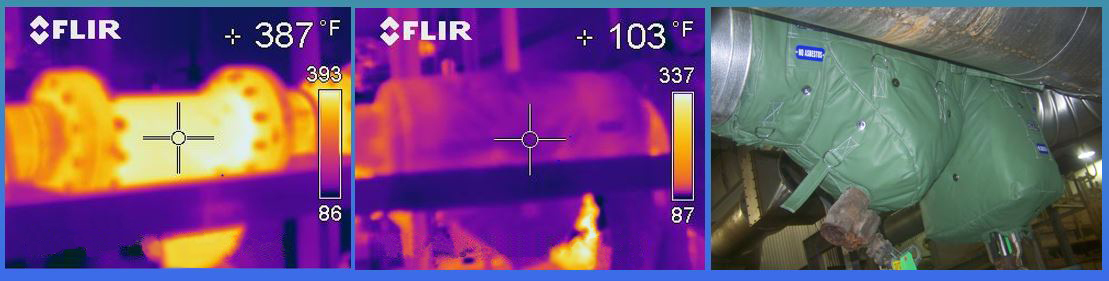

Properly designed and manufactured Thermal Insulation Blankets are a valuable worker safety measure. Insulation blankets will provide an insulated barrier between the high temperature equipment and personnel, and thereby help prevent contact burns from hot equipment surfaces.

Take for instance, a gate valve or other equipment that has a bare radiant heat temperature of 387° F . With installation of a Shannon blanket, correct for the condition, the radiant temperature can be reduced to under 105° F.

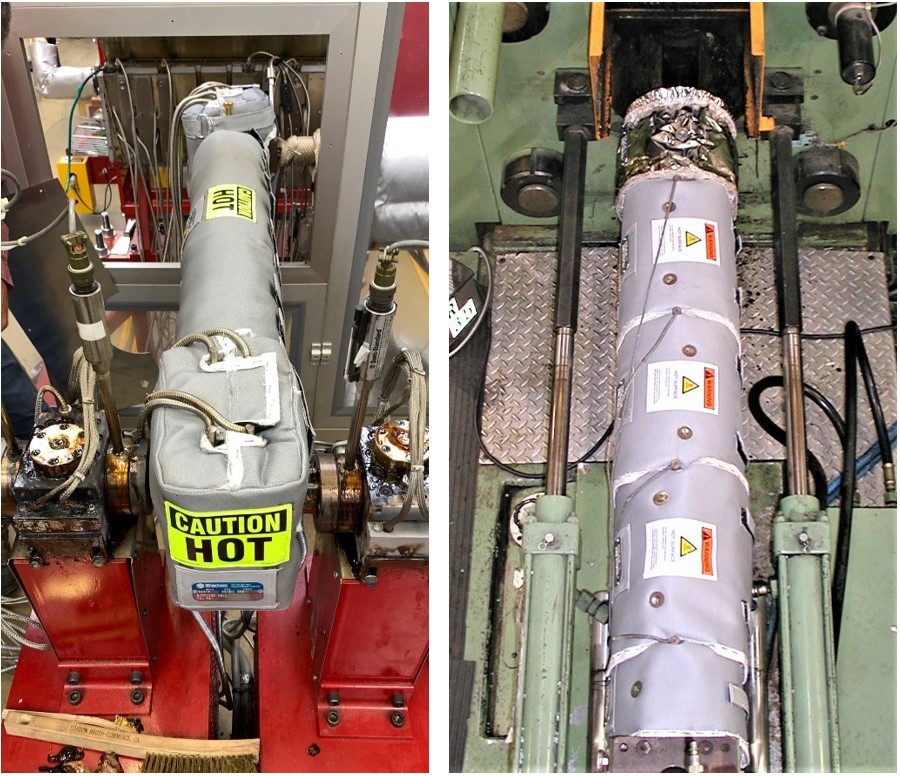

More examples of hot equipment insulated with a Shannon GES solution.

Shown are an insulated Tire Press at a Tire Manufacturer and an insulated Legger Buck Press at a Commercial Laundry Services firm. All Shannon Insulation blankets specs are designed and produced for the customer’s equipment and operating condition. All are removable and reusable for easy access to equipment for inspection and maintenance.

Utilizing a system of thermal blanket insulation will also lower the ambient temperature in mechanical rooms, creating a more comfortable work environment and easing issues of heat stress.

Shannon Thermal Blankets can also be designed with hazard communication labels to inform employees about the equipment beneath.

Contact us for more information about Shannon Thermal Blanket insulation for your application.