Prevention Through Design – Acoustic & Thermal Safety

Prevention through Design or PtD, is an approach to Occupational Health & Safety that addresses safety needs in the design or redesign process to prevent or minimize work related hazards and risks associated with construction, manufacture, use, and maintenance of facilities and equipment. https://www.cdc.gov/niosh/topics/ptd/default.html

PtD Advantages

The main advantage is that the ability to influence key project goals is greatest early in the project schedule during planning, engineering, and design (before resources are deployed and costs mount).

Workplace safety can be Designed-in to the project.

Various organizations are on board. The American Society of Safety Professionals(AMSSP) has created a PtD Design standard ANSI/ASSP z590.3 to help safety professionals and their employers incorporate Prevention through Design concepts into their decision-making. The US Green Building Council (USGBC), which sets LEED policy, is testing pilot credit for PtD for new construction. According to the website, the intent is to “support high-performance cost-effective employee safety and health outcomes across building life-cycle through early attention to safety and health hazards”.

Key elements of the LEED pilot credit are:

- Beginning in pre-design and continuing throughout the design phases, identify and use opportunities to achieve safety and health synergies not only for Construction but also for Operations & Maintenance.

- Perform safety design reviews before the completion of schematic design to explore how the completed building will be operated and maintained over its expected lifetime. https://www.usgbc.org/credits/preventionthroughdesign

Three Steps towards PtD

The National Society of Professional Engineers(nspe.org) suggests these steps for design teams:

- Culture- Establish a lifecycle safety culture

- Processes- Establish processes to enable the safety culture

- Partners: Team up with organizations that value lifecycle safety

PtD Design review basics:

- Hazard Identification: Know the risks

- Risk assessment: Evaluate the severity and likelihood

- Design Options: Identify and select design alternatives for mitigation

Acoustic & Thermal Safety – How is Prevention through Design utilized?

Acoustic and thermal safety are of paramount importance when dealing with HVAC, steam, and power generation systems. Identifying these factors in the design phase can lead to a safer, more efficient project.

By addressing Acoustic Safety: Noise Reduction, and Thermal Safety: Ambient Heat Reduction & Burn Protection, in the design or redesign phase of a facility’s systems, a safer workplace can be created to help prevent hearing loss, burns, and heat related issues in high temperature equipment rooms.

Engineering Design Specifications for Blanket Insulation

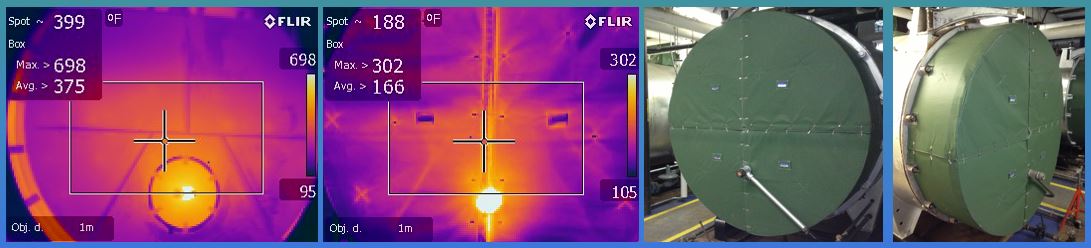

Shannon Thermal Blanket Insulation for complex equipment surfaces, can be specified by engineers for equipment and fittings for boiler rooms, mechanical rooms, and high temperature processing equipment. They not only enhance safety, but also offer energy efficiency improvement as well.

Shannon Acoustic Blanket Insulation systems can provide noise reduction of 4-15 dBA, addressing peak frequency, OSHA compliance and community noise ordinances. Engineers can specify Shannon acoustic blankets for applications such as chillers, compressors, pumps, fans, blowers, silencers, and gas transmission pipelines.

We engineer and manufacture the fitted insulation blanket system appropriate to the application for performance, conditions, and geometry. Shannon Global Energy Solutions’ Removable Reusable Blanket Insulation systems provide capital projects with lifecycle improvements to safety and sustainability.

Partner with us for safety!

Contact us today for more information on specifying Shannon GES for your new or retrofit project.