In the insulation business, small errors can have major effects on safety, as well as energy efficiency. Whether you hire a contractor or major company to design your insulation projects, it is important to be aware when an installer may not be using best practices.

There are three ways that companies and contractors commonly mismanage insulation projects, resulting in additional costs and headaches for both company and client.

“There’s no sense just insulating one valve and leaving all the connections uninsulated.”

#1 – Leaving sections bare

One of the most obvious signs of bad insulation projects is a failure to address an area that needs covering altogether. For example, a company installing insulation may cover a major valve, but leave the connectors to the left and right uncovered. This both allows heat and steam energy to escape, and can pose a safety hazard to workers.

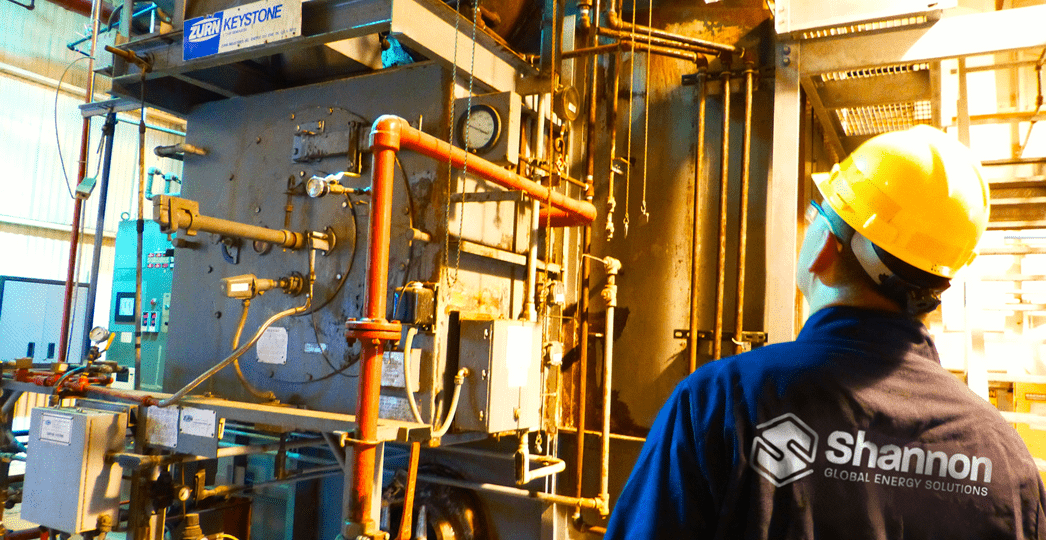

“We would pay attention to everything to the left and right of the valve, and make sure the blankets are covering everything,” said Terry Roach, major accounts manager with Shannon Global Energy Solutions. “There’s no sense just insulating one valve and leaving all the connections uninsulated.”

#2 – Buying insulation from a by-gone era

Another example of a bad insulation job would be the use of obsolete insulation materials. For instance, contractor-made blankets often use a drawstring or hog-ring design, which use wire or cord to affix the blanket to the pipe or valve. These types of blankets can leave large gaps for heat to escape, negatively affecting the efficiency of the facility.

More modern insulation techniques can also fail if applied in the wrong situation. In a manhole environment, the build-up of water and carbonic acid makes fiberglass insulation a no-go.

“If you put the wrong blanket design in a manhole application like that, it can prematurely deteriorate,” said Roach.

This forces the client to replace the insulation blanket before the end of normal service life.

#3 – Forgetting the custom fit

Fitted blankets can run into this problem as well if improperly fitted. A holding flap placed over an extremely hot surface can cause the surrounding blanket to deteriorate.

“The inside of the blankets can withstand the heat, but the outside cannot withstand the same heat,” Roach said. “With a poorly designed blanket, that heat is escaping and deteriorating the outside of the blanket.”

Large bonnets in particular can run into fitting problems like this, where drawstring or overcomplicated flap designs make blankets ineffective and difficult to maintain.

“We would typically design that blanket with capped ends on it that meet up tightly, to eliminate those gaps,” Roach said.