“We go through the facility and look for things traditional insulators don’t cover,” said Ron Smith, inside sales manager for Shannon

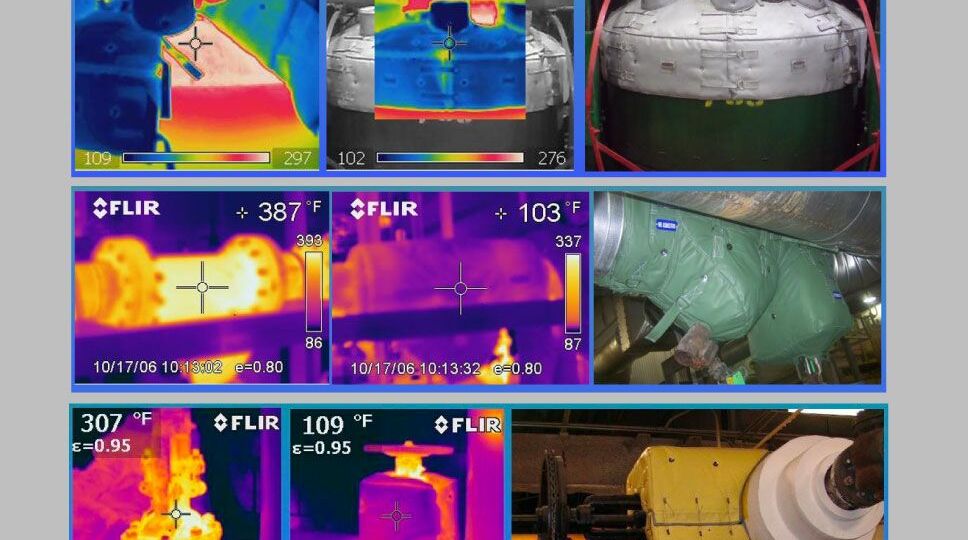

Conventional insulation contractors often leave control valves, strainers, certain flanges, and other components with complex geometry unaddressed, which, in turn, leaves big gaps in any effort to conserve energy with insulation. However, carefully fitting reusable insulation blankets and shields to these components will instead greatly minimize heat loss and improve safety, while being easy for maintenance teams to access and reinstall.

Other applications for insulation

“The difference between standard applications and the unique ones is that facility owners aren’t usually worried about energy conservation when it comes the latter,” said Smith. “They’re trying to fix a problem.”

The unique applications vary significantly in scope, from something as small as covering a standard meat smoker (to better retain heat) to a large-scale acoustic blanket project meant to mitigate sound energy and withstand different temperatures and environments.

Shannon Rain Shields are an example of a reusable solution for a unique, sometimes harsh, environment. Food and beverage plants need to maintain strict sanitation conditions and require regular chemical washdown of equipment. To avoid damaging sensitive components with hot, high-pressure water and sanitizers, plant workers cover certain pieces of equipment on production lines, often multiple times a day, to protect technology that scans packaging or controls motion on a line.

“They cover their equipment, especially electrical components, to perform a washdown,” said Smith. “Often they’re covering it with plastic bags and duct tape.”

Using a Shannon Rain Shield for washdown, solves two problems: First, the shield prevents a washdown from damaging equipment should plastic and tape fail to hold up. And second, the Rain Shield significantly reduces the business’ plastic waste by replacing disposable material with a durable, reusable shield that can last years.

Facility owners and operators can apply thermal and acoustic reusable insulation as well as Rain Shields in different ways, across many industrial settings. When blanket and shield designers account for the variables inherent with unique applications, they ensure buyers get the best performance. Whether the goal is to conserve energy with insulation or protect equipment, Shannon does that and more equally well.