One of the most reliable ways for energy managers and plant operators to reduce energy consumption is by installing insulation blankets on steam lines. When carrying out routine maintenance, workers often remove this insulation. So, experts including the U.S. Department of Energy say, the key to long-term energy savings is developing a strategy employing reusable insulation. The Energy Department’s Advanced Manufacturing Office suggests that plant and maintenance engineers “use removable insulation on components requiring periodic inspections and repair.” Done right, it’s a way to save millions of Btu/h within less than a year, increase safety and profitability and even go green. Several factors derail efforts to get the most out of insulation blankets.

Insulating correctly and with a material offering a high R-Value can be complicated because everything on a piping system should be insulated including geometrically complex fittings. R-Value, or resistance value, measures how well insulation prevents heat from flowing through an insulation material. The higher the R-Value the better job the insulation blankets do of reducing heat transfer.

Remember the importance of specifications and standards

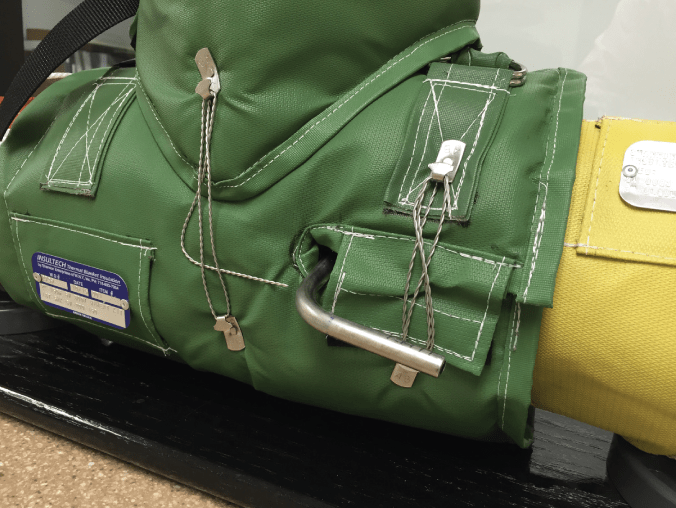

The benefits of insulating steam piping prevent excessive condensate from overloading steam traps. In the case of water lines, insulation blankets prevent dew point conditions and accelerated corrosion. While piping is commonly insulated, components like valves and flanges are not. A word of caution: High temperature can cause an insulation blanket’s fasteners and jacketing to fail, unless designed according to a set of standards that account for the application and specifications and tests such as those from ISO, ASTM and UL.

The benefits of insulating steam piping prevent excessive condensate from overloading steam traps. In the case of water lines, insulation blankets prevent dew point conditions and accelerated corrosion. While piping is commonly insulated, components like valves and flanges are not. A word of caution: High temperature can cause an insulation blanket’s fasteners and jacketing to fail, unless designed according to a set of standards that account for the application and specifications and tests such as those from ISO, ASTM and UL.

“We actually teach the value of removable insulation in the Certified Industrial Energy Professional (CIEP) course that we offer,” notes Tim Janos, director of special projects for the Association of Energy Engineers.

“We recommend putting removable insulation blankets on from the outset, but maintenance folks aren’t energy folks. When they repair a leaking valve, the as-built insulation material comes off, sometimes damaged, and it’s not always replaced. Fixing a leak takes priority over saving energy.”

Getting help

To help plant and district managers tackle the job of installing insulation, several organizations have resources. The North American Insulation Manufacturers Association developed software called 3E Plus® to help engineers and plant managers calculate the appropriate thickness of insulation for a variety of applications. Shannon Global Energy Solutions, which makes Insultech® thermal and acoustic blanket insulation, offers free energy surveys to develop an Energy Conservation Measure for thermal blanket insulation.

Judging what’s appropriate in the way of an insulation blanket means looking at measures such as K-Factor, or thermal conductivity. K-Factor measures the BTUs moving through an inch-thick piece of insulation per hour over a one-square-foot area for every degree of Fahrenheit change. And there are many different insulation materials such as E-glass, rock wool and aerogel. Although the U.S. Department of Health and Human Services recommends use of personal protective equipment when working with aerogels “to minimize reported health effects.”

“Most insulation surveys address pipe and ignore the greatest opportunity, complex valves and fittings,” says Frank Kovacs, president of Shannon. “To correctly design and fit reusable insulation, a manufacturer needs an education in steam process systems and energy survey fundamentals.”

A proper audit is the key to knowing exactly where the energy-savings and payback opportunities lie. It’s also important to know how to compile the field data to present energy savings and get immediate approval from utility rebate programs if available.