ACOUSTIC BLANKETS

ADDRESSING RADIANT NOISE ON FAN & BLOWER HOUSINGS

Shannon GES has developed noise reduction solutions to address radiant sound energy on fan and blower housings. Design considerations for temperature and environmental conditions, as well as noise reduction targets (4-15 dBa). Shannon GES Acoustic Blankets Solutions are ASTM tested, field validated and OEM endorsed. A self-contained insulation system, designed to fit complex surface geometry, integral fasteners make installation quick and easy.

Application: Industrial Fan Housing

Design: LT450A-TT – 2” Thickness

2.9lb/SF – Surface Mass

Reduction: 8-10 dBa

DESIGN FEATURES

- PTFE Fiberglass Jacketing

- Double Sewn / Tri-Fold Binding Edges

- Stainless Steel Integral Fasteners

- Velcro / Vinyl Acoustic Flaps

- Stainless Steel Embossed / ID Tags

- CAD/CNC/ERP Approach for Quality Fit / Finish

- Testing: ASTM: E1222 & ISO 15665 (Insertion Loss Test)

- 4 dBa to 15 dBa Reduction

Application: Rooftop Axial Fan Housing

Design: LT450A-TT – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 6 dBa

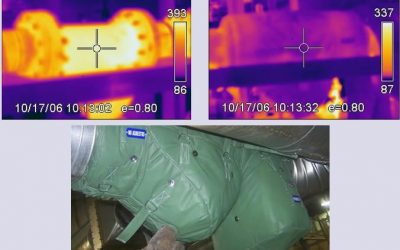

HVAC LIQUID CHILLER

COMPRESSOR, COMPRESSOR INLET, MOTOR HOUSING

Design: LT250A-VP

Performance: 4.0-5.0 dBA Reduction

24” PROCESS PIPING

Design: LT450A-TT

Performance: 10-12 dBA Reduction

Application: Single Stage Compressor Housing

Design: LT450A-TT – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 6 dBa

Application: Single Stage Blower Housing

Design: LT450A-TT – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 8 dBa

Application: Single Stage Centrifugal Compressor Housing

Design: LT450A-TT – 2” Thickness

2.8lb/SF – Surface Mass

Reduction: 8-10 dBa

Application: Inline Axial Fan Housing

Design: LT450A-TT – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 6 dBa

Application: Single Stage Compressor Housing

Design: LT450A-TT – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 6 dBa

Application: Fan Housing

Design: LT250A-VP – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 6 dBa

Application: Forced Draft Fan Housing

Design: LT450A-TT – 1 ½” Thickness

2.4lb/SF – Surface Mass

Reduction: 6 dBa

RELATED ARTICLES

Medical center saves energy, cuts emissions with reusable insulation

The University of Maryland Medical Center (UMMC) in Baltimore operates four central plants delivering steam to a 2.1-million-sq.-ft. teaching hospital, which includes the 294,000-sq.-ft. Homer Gudelsky Building erected in 1994 and the R. Adams Cowley Shock Trauma...

Mill Nets 300% ROI, Improved Safety with Reusable Insulation Project

ROI with Reusable Insulation Since 2011, a paper mill has saved $400,000 on a $95,000 investment in reusable Shannon insulation blankets on approximately 400 steam fittings on one of its paper machines. Generally, reusable insulation projects offer economic...

Do you know these four do’s and taboos of energy surveys?

For building managers and utility supervisors alike, installing new insulation can seem like a daunting task, particularly regarding financials. Fortunately, Shannon representatives can help clients through the process of fitting and installing new reusable blanket...